If your handle wobbles, makes unusual noises, or shows visible damage, it’s a warning sign of looseness that you shouldn’t ignore. You may notice difficulty turning, increased play when pressing or pulling, rust, or loose fasteners. These issues can lead to larger mechanical problems or safety hazards if left unchecked. Addressing early signs can save you from costly repairs later. Stay alert—more tips on keeping your handles secure are just ahead.

Key Takeaways

- Detect handle movement, wobbling, or rattling during inspection, indicating potential looseness.

- Look for visible gaps, shifting, or damage around connection points.

- Listen for unusual noises like squeaks or grinding when handling or operating.

- Check for increased resistance or jerking motions that signal mechanical issues.

- Regularly inspect for rust, corrosion, or material deterioration that weaken handle stability.

Wobbly Door Handles and Their Implications

A wobbly door handle might seem like a minor annoyance, but it can indicate underlying issues that compromise your door’s security and functionality. Loose handles often result from worn-out parts or degraded connections, making door operation unreliable. To fix this, start with door handle lubrication; applying a suitable lubricant can tighten loose components and restore smooth movement. If lubrication doesn’t resolve the wobbling, handle replacement options are available. You may choose between repairing the existing handle or installing a new one altogether, depending on its condition. Regular maintenance can help identify early signs of wear and prevent future problems. Additionally, door hardware inspection can reveal potential vulnerabilities before they become serious issues. Handling the issue promptly prevents further damage and maintains your door’s security. Ignoring a loose handle can lead to worse problems, so addressing it early keeps your door functioning properly and ensures your safety. Regularly checking door components is an effective way to catch issues before they escalate, especially since wear patterns can develop over time. Moreover, understanding the signs of hardware failure can help you act quickly before a minor issue becomes a costly repair.

Unusual Noises When Operating Handles

Unusual noises when operating door handles often signal underlying issues with the handle mechanism or its connections. You might hear squeaks, creaks, or grinding sounds, indicating problems such as loose components or worn parts. The handle material and design play a role in these noises; for example, metal handles may produce different sounds than plastic or composite ones. Handles with intricate designs or poorly fitted parts are more prone to noise. Paying attention to these sounds—early warning signs—can prevent more significant handle issues later on. For example, support breakfast options like cozy accommodations with maintenance-friendly features can help extend the lifespan of handle systems. Incorporating creative storytelling techniques can also help in educating users about maintenance and troubleshooting, leading to better care and longevity of the handles. Additionally, understanding the design differences can aid in diagnosing specific noise issues more accurately, especially when considering the thermal behavior of different handle materials under varying conditions.

Visible Wear or Damage on Handle Components

Look closely at your handle components for any cracks or fractures that might compromise their strength. Check if screws are loose or missing, as this can cause instability. Also, inspect for warped or bent parts that could affect proper operation and safety. Regular inspection helps prevent wear and tear from leading to more serious issues. Additionally, staying vigilant about handle integrity ensures safe and efficient woodworking practices. Recognizing early signs of auditory processing challenges can also help in addressing underlying issues before they worsen. Monitoring for performance cookies can aid in identifying unexpected handle performance issues that might require maintenance. Being aware of material fatigue can help anticipate potential failures before they occur.

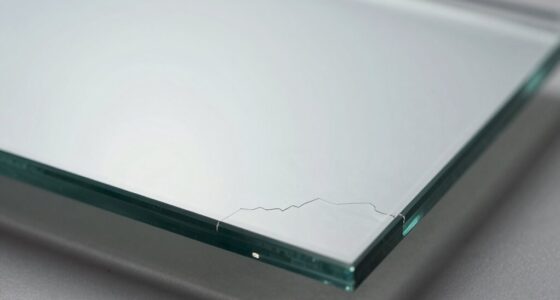

Cracks or Fractures Visible

Visible cracks or fractures on handle components indicate structural damage that can compromise the handle’s integrity. These surface fractures, often appearing as fine lines or splits, weaken the material and increase the risk of sudden failure. When you notice visible cracks, it’s a clear sign that the handle has experienced stress or wear that’s beyond normal. Ignoring these signs can lead to handle failure, potentially causing injury or further damage to the equipment. Carefully inspect the handle for any surface fractures, especially around joints or load-bearing areas. If cracks are present, it’s essential to replace or repair the handle promptly to ensure safety and prevent unexpected breakage. Never underestimate the importance of addressing visible damage early, as Structural integrity is crucial for safe equipment operation and can prevent potential hazards. Regular maintenance and early detection can help identify such issues before they escalate, preserving the overall safety performance of the equipment. Additionally, understanding the wear and tear process can help in planning timely replacements and avoiding accidents. Being aware of material fatigue signs allows for more proactive maintenance and reduces the risk of sudden handle failure.

Loose or Missing Screws

Loose or missing screws on handle components can considerably weaken the overall structure and lead to instability. When screws loosen or fall out, your handle may wobble or feel insecure, making lock installation and handle replacement more difficult. Regularly inspect your handles for signs of wear, such as stripped or damaged screw holes, and tighten any loose screws promptly. If screws are missing or damaged beyond repair, replacing them guarantees your handle remains secure. Ignoring this issue can compromise the lock’s effectiveness and increase the risk of failure. Always use the correct screw size and type to maintain safety and functionality. Additionally, staying informed about hardware innovations can help you select more durable replacement parts and prevent future issues. Being aware of natural pool options can also contribute to a safer backyard environment. Addressing loose screws early helps prevent further damage and keeps your hardware operating smoothly and safely, especially when considering maintenance practices for long-term durability.

Warped or Bent Parts

Warped or bent handle components can markedly weaken their structural integrity and compromise security. Over time, metal fatigue from repeated use or improper installation can cause parts to warp or bend unexpectedly. When this happens, your handle becomes less reliable, increasing the risk of sudden failure. Keep an eye out for:

- Visible warping or bending on handle parts

- Cracks or splits in the material

- Loose or wobbly handles despite tightening

- Uneven or misaligned components

- Signs of corrosion or rust around bent areas

Addressing these issues early prevents further damage and potential accidents. Damaged parts may seem minor but can considerably reduce handle strength. Always inspect for visible wear or damage, especially if you notice handle looseness or unusual movement. Regular maintenance and proper installation can help prevent these issues from developing.

Difficulty Turning or Operating Handles

When handles become difficult to turn or operate, it often indicates a problem with their fit or internal mechanism. You might notice resistance, stiffness, or the handle feeling stuck. This can happen if the handle isn’t properly lubricated, causing friction that makes turning harder. Applying handle lubrication can often resolve this issue, easing movement without the need for replacement. However, if lubrication doesn’t improve the situation, it may be time to contemplate handle replacement. Worn-out or damaged components inside the handle assembly can hinder smooth operation, so inspecting the handle for signs of wear is essential. Addressing these issues early prevents further damage and ensures your handles function safely and effectively.

Handle Movement or Play When Pressed or Pulled

When you notice the handle moves or wobbles when pressed or pulled, it’s a sign of play or looseness. This movement can stem from worn components or loose fasteners that need tightening. Identifying the cause helps you decide whether it’s a simple fix or if parts need replacement. Regular maintenance can prevent further damage and ensure dog bed longevity for your pet’s comfort. Additionally, understanding industry trends in hardware design can help you choose more durable replacements in the future.

Detecting Handle Play

Detecting handle play involves checking for unwanted movement or looseness when you press or pull the handle. You want to pay attention to how the handle feels and responds. The handle material can influence its stability; softer materials might be more prone to looseness over time. Handle design also plays a role—some designs are more secure, while others allow more play. To assess, try gently wiggling the handle in different directions to see if it moves excessively. Look for signs like a loose grip or rattling sounds. Regularly inspecting the handle’s fit helps catch early signs of looseness before it worsens. Remember, identifying these signs early can save you time and money down the line.

Causes of Handle Looseness

Handle looseness often results from worn or damaged components within the handle assembly. Over time, repeated use can cause parts like the handle material—whether plastic, metal, or rubber—to weaken or crack, leading to movement. The handle color might fade or become discolored, signaling material degradation. Loose screws or bolts securing the handle can also contribute to play when pressed or pulled. If the handle material is brittle or the handle color has faded unevenly, it indicates aging or exposure to elements that compromise integrity. Additionally, internal components like springs or bushings may wear out, making the handle feel loose. Understanding these causes helps you identify when repairs are needed before the handle completely fails.

Leaking or Dripping From Connected Fixtures

A common sign of handle looseness is water leaking or dripping from connected fixtures. This often indicates that the handle isn’t sealing properly, which can be worsened by pipe corrosion or fluctuating water pressure. If you notice drips, check for these signs:

- Constant dripping even when the handle is off

- Rust or mineral buildup around fixtures

- Unusual pipe noises or hissing sounds

- Increased water bills

- Visible moisture or pooling around connections

Leaking can cause further damage if ignored, and pipe corrosion may weaken fittings over time. Sudden changes in water pressure might also loosen connections, leading to leaks. Addressing leaks early helps prevent costly repairs and keeps your plumbing in good shape.

Rust or Corrosion Around Handle Areas

You might notice rust or corrosion around handle areas, which signals material breakdown over time. These signs can weaken the handle’s stability and lead to looseness if left unaddressed. Regular maintenance, like cleaning and applying protective coatings, helps prevent further damage and keeps your handles secure.

Signs of Material Breakdown

Rust or corrosion around handle areas often indicate underlying material breakdown that can compromise the handle’s integrity. This deterioration signals issues like material fatigue or manufacturing defects, which weaken the handle over time. Watch for:

- Visible rust patches or corrosion spots

- Flaking or peeling paint near handles

- Cracks or splits in the handle material

- Loose or wobbly handle movement

- Accelerated wear compared to similar handles

These signs suggest the material is degrading, reducing strength and increasing the risk of sudden failure. Ignoring corrosion or rust can lead to more serious problems, such as complete handle failure or accidents. Regular inspection helps catch these signs early, preventing safety hazards linked to compromised handle materials.

Preventive Maintenance Tips

Regularly inspecting handle areas for early signs of rust or corrosion allows you to address issues before they worsen. Preventive maintenance not only preserves functionality but also enhances aesthetic improvements and cosmetic upgrades. To combat rust, apply a protective coating or rust inhibitor to vulnerable spots. Keep handles dry and clean to prevent moisture buildup. Consider replacing corroded parts promptly to avoid further damage.

| Tip | Benefit |

|---|---|

| Apply rust-resistant paint | Protects surfaces |

| Regular cleaning & drying | Prevents moisture |

| Use corrosion inhibitors | Extends lifespan |

| Tighten loose handles | Maintains stability |

| Replace severely corroded parts | Ensures safety |

Following these tips helps you maintain handle integrity, improve appearance, and avoid costly repairs.

Loose Screws or Fasteners Around Handles

Have you noticed handles feeling wobbly or shifting unexpectedly? Loose screws or fasteners around handles are common signs of handle looseness. To address this, start with a quick DIY inspection—tighten any loose screws with a screwdriver. If you find damaged or stripped fasteners, it’s best to contemplate professional repair to avoid further damage. Keep an eye out for:

- Handle wobbling when used

- Screws that appear out of place

- Visible gaps between handle and surface

- Rust or corrosion around fasteners

- Handles that shift with minimal force

Ignoring these signs can lead to more serious issues or accidents. Regularly checking and tightening screws can save you money and trouble later. When in doubt, consulting a professional ensures your handles stay secure and safe.

Sudden Stop or Resistance When Using Handles

If you notice handles suddenly stopping or resisting when you try to use them, it’s a clear sign something isn’t right. This resistance could be due to a lack of handle lubrication, causing parts to stick or seize up. Applying appropriate handle lubrication can often resolve this issue, making the handle move smoothly again. However, if lubrication doesn’t help or the resistance worsens, handle replacement might be necessary. Ignoring this warning can lead to further damage or even safety hazards. Regular maintenance, including checking for proper handle lubrication and replacing worn handles promptly, can prevent sudden stops or resistance. Stay attentive to these signs to keep your handles functioning properly and avoid more costly repairs later.

Handle Looseness Accompanied by Other Mechanical Issues

When handle looseness occurs alongside other mechanical problems, it often signals underlying issues that extend beyond simple wear. You might notice your equipment making unusual noises, vibrations, or inconsistent performance. These signs suggest that your handle looseness is part of a bigger mechanical issue that needs attention. Ignoring these combined symptoms can lead to more severe damage or failure. Be alert for:

- Struggling to operate the handle smoothly

- Unusual sounds when using the handle

- Increased resistance or jerking motions

- Visible damage or wear around connection points

- Sudden changes in performance or responsiveness

Addressing handle looseness early, especially when paired with other mechanical issues, can prevent costly repairs and ensure your equipment remains safe and reliable. Don’t overlook these signs; act promptly.

Frequently Asked Questions

Can Handle Looseness Lead to Complete Hardware Failure?

Yes, handle looseness can lead to complete hardware failure if you ignore it. When the handle becomes loose, it puts extra strain on internal components, causing wear and potential damage. Over time, this can result in hardware failure, disrupting your device’s functionality. To prevent this, you should tighten or repair the handle promptly, avoiding further damage and ensuring your hardware continues to work smoothly.

What Safety Risks Are Associated With Loose Door Handles?

Loose door handles pose significant safety risks, including security concerns and child safety issues. You could accidentally open a door, exposing your home to intruders or allowing children to access dangerous areas. The handle’s instability might cause it to break, leading to sudden falls or injuries. To protect yourself and your loved ones, regularly check and tighten handles and address looseness promptly, ensuring your home remains safe and secure.

How Often Should I Check Door Handles for Signs of Wear?

You should check your door handles for wear inspection at least every three to six months. Studies show that regular handle maintenance reduces accidents by 25%, emphasizing its importance. During these checks, look for looseness, rust, or cracks. Being proactive helps prevent handle failure, which can cause injuries or security issues. So, stick to this schedule to guarantee your handles stay secure and functional, maintaining safety and peace of mind.

Are There Specific Tools Recommended for Tightening Loose Handles?

For handle repair, you’ll want to use tightening tools like a screwdriver or Allen wrench, depending on your handle type. These tools allow you to securely tighten loose handles and prevent further damage. Make sure you select the right size to avoid stripping screws. Regularly checking and tightening handles with these tools keeps them stable and safe, saving you from more extensive repairs down the line.

When Is Professional Repair Necessary Instead of DIY Fixes?

You should seek professional assessment when DIY pitfalls seem risky or if your attempts to tighten a loose handle don’t hold. If the handle is severely damaged, cracked, or keeps loosening despite your efforts, it’s best to call in a pro. Trusting a professional guarantees safety and proper repair, preventing further damage or injury. Don’t risk compromising the fixture’s integrity; when in doubt, get expert help.

Conclusion

Don’t ignore a wobbly door handle—today’s small issue can become tomorrow’s costly repair. If you notice any signs like unusual noises, looseness, or visible damage, act quickly. Think of it as your modern-day alarum, warning you of potential trouble ahead. Addressing these early signs keeps your home safe and doors swinging smoothly, so you won’t be caught off guard when the uninvited guest shows up. Stay vigilant—your home’s integrity depends on it.