A micro-bevel is a tiny, angled edge added to your blade’s main edge that enhances sharpness, improves durability, and simplifies sharpening. By forming at the intersection of grain boundaries and internal stresses, micro-bevels help prevent chips and uneven wear. Thinner micro-bevels excel with softer materials, while rougher ones suit tougher surfaces. Understanding how they form and function can dramatically extend your blade’s life—discover more to optimize your sharpening skills.

Key Takeaways

- Micro-bevels are tiny angled edges added to a blade’s main edge to enhance sharpness and durability.

- They form through dislocation movement at grain boundaries, influenced by material properties and internal stresses.

- Proper micro-bevel angles and geometry balance cutting performance with edge strength for specific tasks.

- Recognizing signs like dullness or chipping helps determine when micro-bevel adjustments are needed.

- Micro-bevels work alongside primary bevels to optimize blade longevity, ease of sharpening, and overall cutting efficiency.

What Are Micro-Bevels and Why Are They Important?

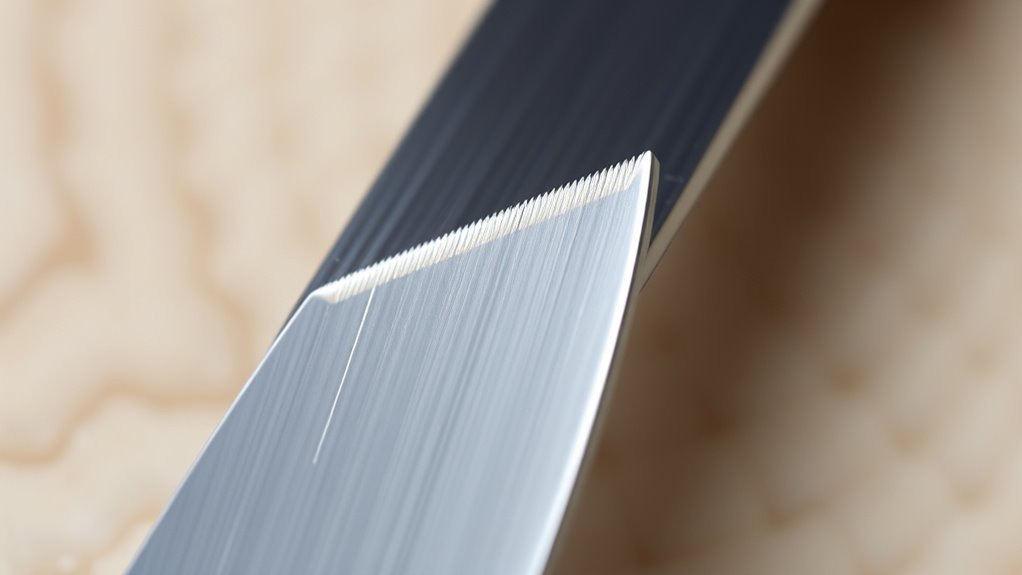

Ever wondered what micro-bevels are and why they matter? Micro-bevels are tiny angled edges added to a blade’s main edge, enhancing performance and durability. They influence blade aesthetics by giving a sleek, refined look that signals sharpness. During manufacturing processes, skilled techniques create these subtle bevels to improve cutting ability and ease sharpening. Micro-bevels help prevent chips and reduce wear, ensuring your blade stays effective longer. They also make maintenance more manageable since a slight re-sharpening can restore the edge without removing too much material. proper micro-bevel design can optimize the balance between sharpness and durability, ensuring a high-performance edge over time. Additionally, understanding these small features highlights how blade maintenance can be simplified, saving time and effort.

The Science Behind Micro-Bevel Formation

Micro-bevel formation is driven by grain boundary dynamics, where internal stresses cause subtle material shifts. You’ll see that the stress effects from cutting forces influence how the edge changes shape, creating that tiny bevel. Additionally, the geometry of the cutting edge plays a vital role in how these microscopic features develop and stabilize. A thorough understanding of quality assurance principles can help in predicting and controlling these subtle edge changes to ensure optimal performance. Recognizing the support breakfast options available can also aid in understanding how proper maintenance and care contribute to the longevity of cutting tools.

Grain Boundary Dynamics

Have you ever wondered how tiny changes at the microscopic level influence the formation of micro-bevels? It all comes down to grain boundary dynamics. A grain boundary is the interface where two crystal grains meet, and it plays a vital role in how your blade’s edge evolves. When dislocation movement occurs near these boundaries, it can cause localized strain, weakening the structure there. This movement facilitates the gradual removal of material along specific planes, shaping the micro-bevel. As dislocations accumulate and glide along grain boundaries, they create small, precise angles that define the micro-bevel’s edge. Understanding these microscopic interactions helps you control how your blade wears and sharpens, making grain boundary dynamics a key element in micro-bevel formation and maintenance. Additionally, South – These Fifty States highlights the importance of detailed regional knowledge in understanding complex systems. Recognizing how material properties influence grain boundary behavior can further refine your approach to blade craftsmanship, especially when considering metallic microstructures and their impact on edge durability. The study of grain boundary migration also provides insight into how microstructural changes occur during sharpening and use. Furthermore, understanding grain boundary behavior can assist in selecting appropriate materials that optimize edge retention and durability over time.

Material Stress Effects

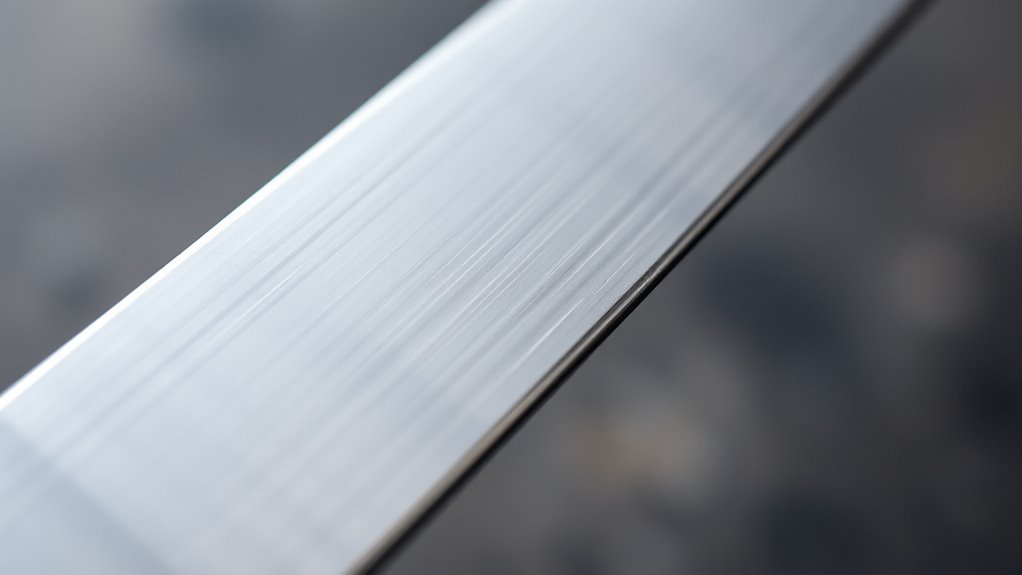

Material stress plays a crucial role in shaping micro-bevels by influencing how the blade’s surface responds to external forces. When you cut or grind, stress concentrates at specific points, leading to localized material fatigue. Over time, these stress concentrations weaken the edge, causing micro-bevels to form or grow. The table below highlights how different factors affect stress distribution:

| Factor | Effect on Micro-Bevels |

|---|---|

| Sharpness of blade | Increases stress concentration at tip |

| Material hardness | Influences fatigue resistance |

| Cutting force | Amplifies stress at contact points |

| Surface finish | Affects stress distribution uniformity |

| Edge geometry | Alters stress pathways |

Understanding these effects helps you predict how micro-bevels develop, ensuring better maintenance and sharper edges over time. Additionally, visual cues can aid in recognizing early signs of stress-related wear, allowing for proactive adjustments. Being aware of material stress factors enables more precise sharpening techniques and prolongs the lifespan of your blades.

Cutting Edge Geometry

The shape and design of a cutting edge directly influence how micro-bevels form and develop over time. Blade curvature affects the way force distributes across the edge, impacting micro-bevel creation and stability. A curved blade concentrates stress differently than a flat one, leading to varied micro-bevel angles during sharpening. Handle ergonomics also play a role; a comfortable grip allows better control, ensuring consistent angle maintenance, precise micro-bevel formation, and blade control techniques. Additionally, blade geometry influences how smoothly a micro-bevel develops, facilitating more consistent edge refinement. When you optimize blade curvature and handle design, you facilitate smoother micro-bevel development, reducing the risk of uneven edges or chipping. Understanding how these factors interact helps you craft a more durable, efficient edge, and prolongs the life of your blade. Proper geometry is key to maintaining a sharp, resilient micro-bevel over time. Additionally, blade material quality influences how well a micro-bevel holds up under use, affecting overall edge durability and performance. Recognizing the importance of micro-bevel stability ensures that your sharpening techniques contribute to a longer-lasting, sharper edge. Moreover, considering manufacturing precision can further enhance the consistency and reliability of your micro-bevels, leading to superior cutting performance.

How to Create a Micro-Bevel on Your Knife

Creating a micro-bevel on your knife is a straightforward process that can considerably improve its cutting performance. To start, choose your sharpening tool—whether a stone or honing rod—and set it to a comfortable angle, typically 15-20 degrees. Lightly draw the blade’s edge across the stone, maintaining consistent pressure and angle, working from heel to tip. This creates a secondary, smaller bevel that enhances sharpness. Historically, micro-bevels evolved as a practical solution across cultures to refine blades efficiently, holding cultural significance in many sharpening traditions. Here’s a quick overview:

| Step | Action | Tip |

|---|---|---|

| 1 | Set the sharpening angle | Keep it consistent for even bevel |

| 2 | Draw blade steadily across | Use light, controlled strokes |

| 3 | Check for a uniform edge | Test on paper for sharpness |

This method ensures a durable, effective micro-bevel. Understanding the importance of proper sharpening techniques can help you achieve the best results and maintain your knives effectively.

Different Types of Micro-Bevels and Their Uses

Understanding the different types of micro-bevels can help you choose the right one for your needs. The bevel angles and their purposes influence how your knife performs, while the materials you use affect durability. Exploring common geometries will show you how to optimize your tool for specific tasks. Additionally, recognizing passive voice in your writing can make your explanations clearer and more direct.

Bevel Angles and Purposes

Different micro-bevel angles serve specific purposes, making them essential tools for precise sharpening and maintenance. Your bevel angle selection influences how well your edge performs and how durable it remains. A steeper micro-bevel (around 20°–25°) enhances cutting power for tough materials, while a shallower angle (around 15°–18°) improves finesse for delicate tasks. Each micro bevel purpose aligns with these angles to optimize performance. Here’s a quick guide:

| Bevel Angle | Micro Bevel Purpose | Best For |

|---|---|---|

| 15°–18° | Fine, precise cuts | Kitchen knives, razors |

| 20°–25° | Heavy-duty tasks | Hunting, camping knives |

| 10°–14° | Extremely delicate cuts | Surgical or craft blades |

| 25°–30° | Extra durability | Chopping, rugged tools |

| 18°–20° | Balanced performance | General use, multi-purpose |

Understanding the micro-bevel angles helps in choosing the right configuration for your specific needs and extends the lifespan of your blades.

Materials Suitability for Micro-Bevels

Have you ever wondered which micro-bevels work best with specific materials? Your choice depends on material compatibility and desired wear resistance. Here are three key types:

- Fine micro-bevels for soft materials – Ideal for delicate items like paper or soft wood, offering precision without compromising the edge. Understanding material properties is essential to select the appropriate micro-bevel. Additionally, softer materials may benefit from low-angle micro-bevels to minimize stress and prevent damage.

- Medium micro-bevels for general use – Suitable for most metals and plastics, balancing durability and sharpness. These micro-bevels are versatile and commonly used across various applications.

- Rough micro-bevels for hard or abrasive materials – Designed for tough tools like carbide, providing high wear resistance and longevity. Selecting the correct micro-bevel type ensures your edge stays sharp longer and resists wear. Understanding material properties of your tools helps you choose the most effective micro-bevel type for each application.

Common Micro-Bevel Geometries

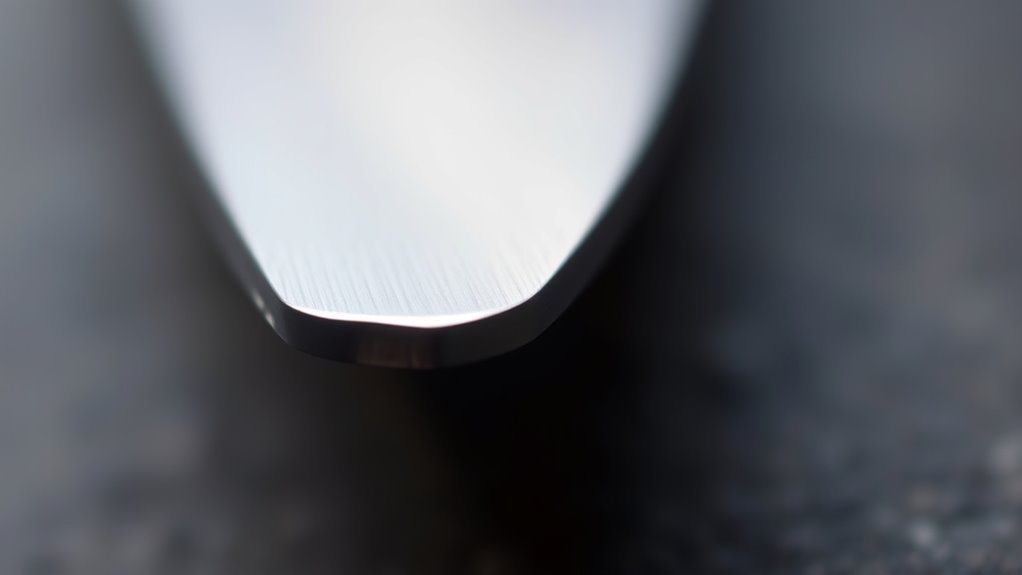

Choosing the right micro-bevel geometry can substantially impact your tool’s cutting performance and durability. Common micro-bevel geometries include flat, V-shaped, and convex designs, each suited for different tasks. Flat micro-bevels offer a sharp, precise edge ideal for fine detail work, while V-shaped micro-bevels provide strength and resilience, suitable for tougher materials. Convex micro-bevels enhance edge stability and reduce chipping, making them perfect for heavy-duty use. Blade compatibility depends on manufacturing techniques; some bevels are easier to produce with laser sharpening, while others rely on traditional grinding. Selecting the appropriate micro-bevel geometry ensures best performance and longevity, aligning with your specific cutting needs and the manufacturing processes involved. Additionally, understanding the micro-bevel manufacturing techniques can help you choose blades that maintain their edge longer and perform more reliably over time. Moreover, being aware of cutting edge geometry can inform your decisions about blade selection for various applications.

Signs That Indicate the Need for a Micro-Bevel

One clear sign you need a micro-bevel is when your blade begins to dull quickly or loses its sharp edge after minimal use. If your blade’s aesthetics show chipping or uneven wear, it’s a red flag that a micro-bevel could help. Additionally, manufacturing specifications often recommend micro-bevels for specific blade types to maintain ideal performance. Here are some signs to watch for:

- Your blade struggles with clean cuts, indicating it’s losing precision.

- The edge feels rough or jagged, rather than smooth and refined.

- You notice consistent dullness despite sharpening efforts, suggesting an uneven edge that a micro-bevel can improve.

- When the blade’s sharpness diminishes faster than expected, it’s often due to improper edge geometry that a micro-bevel can correct.

Paying attention to these signs ensures your blade stays sharp and effective.

Micro-Bevels vs. Primary Bevels: Key Differences

Understanding the key differences between micro-bevels and primary bevels is essential for selecting the right edge for your cutting tools. Primary bevels form the main cutting edge, providing strength and overall bevel aesthetics, but they may be thicker and less precise. Micro-bevels, on the other hand, are small angles added at the apex of the primary bevel, creating a finer, sharper edge. Micro-bevels can enhance edge durability by reducing stress on the main bevel, preventing chips and damage. While they improve precision and fine control, micro-bevels often result in a more refined bevel aesthetics. In contrast, primary bevels give a bold, more robust look, but may sacrifice some finesse. Knowing these differences helps you balance edge durability with desired appearance and cutting performance.

Tips for Maintaining and Sharpening Micro-Bevels

To keep your micro-bevels sharp and effective, regular maintenance is essential. Proper sharpening routines help maintain blade durability and maximize edge retention. Here are three tips to keep your micro-bevels in top shape:

Keep your micro-bevels sharp with regular, gentle touch-ups and proper tool cleaning.

- Use a fine-grit stone or honing rod to gently touch up the micro-bevel, preserving its precision.

- Avoid over-sharpening, which can erode the micro-bevel and weaken the edge over time.

- Regularly clean your sharpening tools to prevent debris from dulling the micro-bevel during maintenance.

Common Mistakes to Avoid When Adding a Micro-Bevel

Adding a micro-bevel can considerably improve your blade’s cutting performance, but it’s easy to make mistakes that compromise the edge. One common mistake is overextending the micro-bevel, which can weaken edge durability and lead to quicker dulling. Using improper sharpening techniques, such as applying uneven pressure or not maintaining a consistent angle, can also create an inconsistent bevel that harms the edge. Another error is rushing the process; rushing leads to misaligned angles and a fragile edge. Additionally, neglecting to clean your blade thoroughly before sharpening can cause debris buildup, affecting the micro-bevel’s precision. To avoid these pitfalls, focus on steady, deliberate sharpening techniques, and always maintain a consistent angle to ensure your micro-bevel enhances, rather than damages, your blade’s performance.

Frequently Asked Questions

Can Micro-Bevels Be Applied to All Types of Knives?

Yes, micro-bevels can be applied to most knife types, but you should consider blade materials and handle compatibility first. Harder steels may require specific sharpening angles, while softer steels can handle more aggressive micro-bevels. Confirm your handle can support the added reinforcement without compromising balance. With proper technique, micro-bevels enhance edge durability across various knives, making them a versatile addition regardless of the blade material.

How Often Should I Re-Sharpen My Micro-Bevel?

You should re-sharpen your micro-bevel when you notice a decline in your knife’s cutting performance, typically every few months or after 10-15 uses. Maintain a consistent maintenance schedule, and adjust sharpening frequency based on how often you use your knife. Regularly inspecting your micro-bevel guarantees it stays sharp and effective. This proactive approach keeps your edges in top shape and prolongs the lifespan of your knife.

Does the Angle of the Micro-Bevel Affect Cutting Performance?

Think of your micro-bevel’s angle as the steering wheel of a finely-tuned knife—small changes make a big difference. The angle impact directly influences cutting efficiency; a steeper micro-bevel may improve precision but can weaken the edge, while a shallower one offers durability but less finesse. Adjusting this angle carefully balances sharpness and strength, ensuring your knife performs ideally for your specific tasks.

Are Micro-Bevels Suitable for Serrated or Only Straight-Edged Knives?

Micro-bevels are suitable for both serrated knives and straight-edged knives. For serrated knives, micro-bevels can improve the sharpness and ease of cutting through tough or fibrous materials. With straight-edged knives, micro-bevels help maintain a fine, durable edge that slices smoothly. In both cases, adding a micro-bevel enhances performance, prolongs edge life, and makes sharpening more manageable, making them a versatile feature for various knife types.

Can Micro-Bevels Be Added to Damaged or Dull Edges?

Yes, you can add micro-bevels to damaged or dull edges to improve edge repair and bevel correction. Carefully re-establish the bevel with a sharpening stone or system, then create a micro-bevel to enhance cutting performance. This small adjustment helps realign the edge, making it sharper and more durable. Just make certain you don’t remove too much material, and take your time to achieve a precise, effective micro-bevel.

Conclusion

Mastering micro-bevels can transform your sharpening game, turning a dull edge into a razor-sharp weapon. By paying attention to these tiny details, you’ll extend your knife’s life and cut with surgical precision. Don’t underestimate the power of a well-crafted micro-bevel—it’s the secret weapon that can save your edge from the brink of destruction. With practice, you’ll wield your knives like a culinary ninja, conquering every task with effortless finesse.