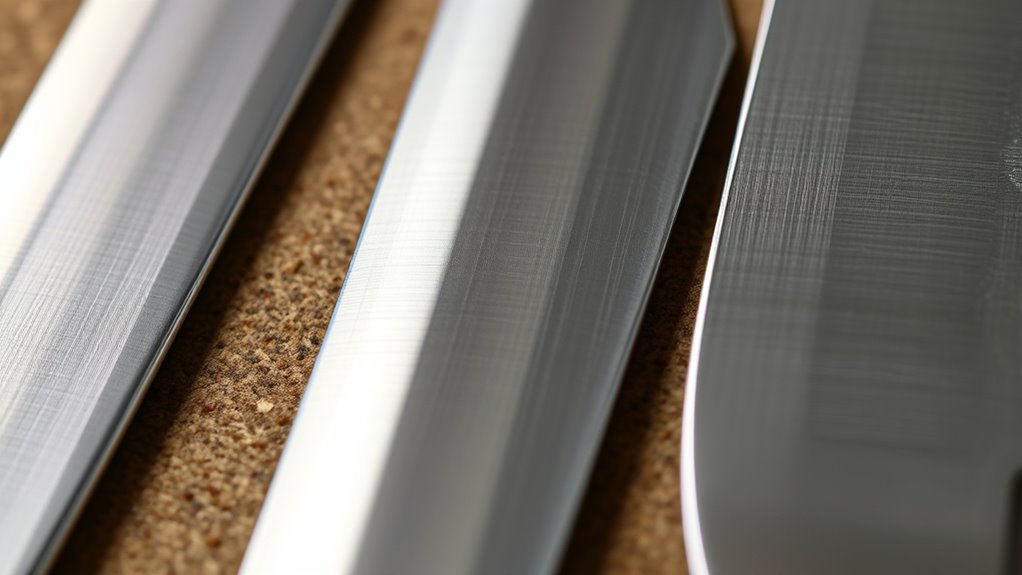

Knowing the difference between flat, hollow, and convex knife grinds helps you understand why your cuts feel different. A hollow grind creates a very sharp, thin edge perfect for precise slicing, but it’s less durable for heavy use. Flat grinds offer a balanced profile ideal for versatile tasks, while convex grinds provide strength and stability for tough cuts. Understanding these differences is key; explore further to see which grind suits your needs best.

Key Takeaways

- Hollow grinds produce a very sharp, thin edge ideal for delicate slicing but less resistant to impact or shock.

- Flat grinds offer a balanced, versatile cutting profile suitable for various tasks, providing predictable control.

- Convex grinds feature a curved bevel that supports a stronger, more durable edge for heavy-duty chopping and demanding environments.

- The grind type influences cutting feel: hollow is smooth and precise, flat is balanced, convex is powerful and stable.

- Different grinds require specific sharpening techniques and maintenance to preserve their unique edge characteristics.

What Is a Hollow Grind and How Does It Work?

Have you ever wondered how a hollow grind creates such a sharp and precise edge? It’s because the grind forms a concave shape along the blade’s edge, making it extremely thin and sharp. This shape reduces the contact area, decreasing friction during cutting, which results in smoother, more effortless slices. The hollow grind is especially effective for precision tasks like slicing soft foods or delicate materials. Plus, because the edge is so thin behind the bevel, sharpening becomes simpler—you just remove minimal material to restore the edge. Additionally, the energy-efficient design of hollow grinds aligns with sustainable practices by reducing unnecessary material removal during sharpening. Moreover, the manufacturing process of hollow grinds often involves specialized equipment to achieve consistent curvature, which can influence the overall quality and performance of the blade. This process also contributes to the uniformity of the edge, ensuring it remains sharp for longer periods. The lightweight profile of hollow-ground knives can also reduce user fatigue during extended use. However, this design isn’t suited for heavy-duty work, as the thin edge can chip or roll under impact. Overall, the hollow grind is ideal when sharpness and finesse matter most in your cutting tasks.

Understanding the Flat Grind and Its Versatility

Wondering why the flat grind is one of the most popular blade grinds? It’s because it strikes a great balance between strength and cutting efficiency. The symmetrical flat bevels run from the spine to the edge, creating a steep V-shape that slices well and handles a variety of tasks. You’ll find it on many kitchen knives, pocket knives, and utility blades because it performs well in slicing, chopping, and general everyday use. The flat grind is also easier to produce compared to other grinds, making it widely available. While it’s not as delicate as hollow grinds, it offers enough durability for most tasks. Its versatility makes it a reliable choice whether you’re preparing food or tackling outdoor projects. Additionally, understanding blade geometry can help in designing or maintaining your knife collection effectively. blade geometry plays a crucial role in determining the overall performance and cutting characteristics of a knife, making it an important aspect for enthusiasts and professionals alike.

The Principles Behind Convex Grinds and Their Strengths

Convex grinds offer exceptional edge support, making them more durable under heavy use and resistant to chipping. This curved bevel distributes impact forces evenly, enhancing the knife’s strength during tough tasks. As a result, convex knives excel in demanding environments where durability and reliability are critical. Additionally, the edge stability provided by convex grinds can contribute to more consistent cutting performance over time. Proper maintenance practices can further extend the benefits of a convex grind, ensuring the knife remains sharp and effective for longer periods. Incorporating proper sharpening techniques helps maintain the convex shape and maximum edge support. Regularly inspecting and adjusting the blade geometry can also help sustain its optimal performance and longevity.

Edge Support and Durability

The key advantage of convex grinds lies in their exceptional edge support, which stems from their curved bevel design. This curvature distributes impact forces evenly along the edge, making it highly resistant to chipping and rolling under heavy use. Because the bevel bows outward, more material remains behind the cutting edge, providing added strength and durability during tough chopping or outdoor tasks. You’ll find that convex edges maintain their sharpness longer and handle shocks better than flatter grinds. While they can be more challenging to sharpen precisely, their robust construction makes them ideal for demanding applications where strength and longevity matter most. The impact resistance of convex edges is a major reason they are favored by professional chefs and outdoor enthusiasts alike. Additionally, the edge support provided by convex grinds helps improve safety by reducing the likelihood of unexpected edge failure during intensive tasks. Furthermore, the durability of convex edges ensures they remain functional over time, even with frequent heavy-duty use. A resilient edge also contributes to maintaining cutting performance in challenging conditions, making convex grinds a preferred choice for rugged environments. This combination of strength and resilience makes convex grinds especially suitable for heavy-duty tasks, where maintaining a sharp edge is critical to performance.

Resistance to Chipping

Why does a convex grind excel at resisting chipping? It’s because the curved bevel distributes impact forces more evenly across the edge. Unlike flat or hollow grinds, which concentrate stress at a narrow point, the convex shape provides extra support behind the cutting edge. This means when you hit hard materials or accidentally strike a bone or stone, the force is absorbed across a broader area, reducing the chance of the edge cracking or chipping. Additionally, the gentle curve helps maintain the integrity of the edge during heavy use. The thicker behind-the-edge profile adds resilience, making convex knives less prone to damage from shock. As a result, they’re ideal for demanding tasks where durability and chipping resistance are vital, like chopping wood or processing tough materials. Proper maintenance and tool steel properties can further enhance their durability and performance.

Comparing Cutting Performance: Which Grind Slices Better?

When it comes to slicing performance, each grind type offers distinct advantages depending on the task. Hollow grinds excel at slicing soft items and precision cuts due to their thin, low-friction edge. Flat grinds provide a balanced approach, suitable for both push and pull cuts, making them versatile for various tasks. Convex grinds combine strength and slicing ability, offering smooth cuts with added durability. To compare:

| Grind Type | Best For | Notable Feature |

|---|---|---|

| Hollow | Precision slicing | Thin, low-friction edge |

| Flat | General use | Balanced strength and efficiency |

| Convex | Heavy-duty work | Strong, resilient edge |

Choose based on your cutting needs: finesse, versatility, or durability.

Durability and Strength: Which Grind Handles Heavy Use?

When it comes to heavy use, the strength and support of your knife’s grind matter a lot. Some grinds offer better resistance to chipping and damage, making them more durable over time. Understanding which grind provides the best structural support can help you choose the right knife for tough tasks. For example, certain security system features like durable construction and weather resistance can be analogous to how a specific grind withstands heavy use, ensuring longevity and performance. Additionally, the zodiac traits associated with resilience and durability can influence how a knife’s design aligns with your needs, especially for demanding applications. Moreover, considering the architectural solutions approach to design can inspire innovative ways to enhance the knife’s durability and functionality. Recognizing the importance of material strength in blade construction further aids in selecting a resilient and long-lasting knife suitable for heavy-duty tasks, especially when choosing tent camping gear that must withstand rugged outdoor conditions.

Structural Support Levels

Convex grinds are the most durable and strongest option for heavy-duty use because their curved bevels provide maximum edge support. This shape distributes force evenly along the edge, making it less prone to chips, rolls, or damage under heavy impact. The thicker behind the edge adds resilience, allowing the knife to withstand chopping, batoning, and rough handling without losing its sharpness quickly. Unlike flat or hollow grinds, convex edges resist deformation from shocks and stresses, maintaining integrity over time. Additionally, convex profiles are favored in vetted outdoor and survival knives for their robustness. Their ability to handle heavy use makes them ideal for demanding environments. The edge stability provided by convex profiles is also beneficial for maintaining a sharp edge during intense cutting tasks. While sharpening requires more skill, the trade-off is a knife built for demanding tasks. If your work involves chopping firewood, bushcraft, or survival situations, a convex grind offers the structural support you need for reliable, long-lasting performance. Moreover, the durability of convex edges ensures they remain effective over prolonged use, reducing the need for frequent sharpening and maintenance. Incorporating proper maintenance techniques can further extend the lifespan of convex edges and keep them performing at their best.

Resistance to Damage

For heavy-duty use, the grind’s ability to resist damage is crucial, and convex edges excel in this area. Their curved, reinforced bevel provides maximum support, making them more resistant to chipping, rolling, and dulling under stress. You’ll find convex grinds ideal for demanding tasks like chopping, batoning, and heavy outdoor work. To better understand why, consider these points:

- Thick Behind the Edge: The convex shape increases material behind the cutting edge, offering enhanced strength.

- Shock Absorption: Its curved profile disperses impact forces, reducing damage risks.

- Chipping Resistance: Less prone to chips when striking hard objects or rough use.

- Edge Retention: Maintains sharpness longer despite heavy use, decreasing frequent sharpening needs.

- Integration with Smart Home Technology: Advanced knife maintenance systems can monitor and alert you when sharpening or honing is needed, enhancing durability and performance. These systems leverage sensor technology to track the condition of your blades in real-time.

This makes convex grinds the top choice for durability and heavy-duty performance.

Maintenance and Sharpening: Tips for Each Type of Grind

Maintaining and sharpening different knife grinds requires tailored techniques to guarantee ideal performance and longevity. For hollow grinds, use a fine stone and focus on sharpening the thin bevel to maintain a sharp edge. Be gentle to prevent chipping or rolling, and regularly hone to keep the edge aligned. Flat grinds are straightforward; use a whetstone or sharpening system to maintain the V-shaped bevel evenly. Consistent angle control is key to avoid uneven wear. Convex grinds are trickier; they often need freehand sharpening on a coarse stone, following the curve naturally. For best results, use a leather strop or finishing stone to refine the edge. Regular maintenance keeps each grind performing at its best, but convex edges especially benefit from careful, consistent sharpening.

Practical Applications for Hollow, Flat, and Convex Knives

Understanding which knife grind suits your task can improve your results. Hollow blades excel at precise slicing, flat grinds are versatile for everyday chores, and convex edges handle heavy-duty work. Choosing the right one depends on the specific application you need to accomplish.

Precise Slicing Tasks

When it comes to precise slicing, choosing the right knife grind can substantially improve your results. Your choice affects how cleanly and smoothly you cut, especially on delicate or detailed tasks.

- Hollow grind excels in slicing soft items like fish or thin meats, thanks to its thin, low-friction edge.

- Flat grind is ideal for slicing vegetables, fruits, or meats evenly, offering a balanced push and pull.

- Convex grind provides strength and stability for cutting hard or tough materials, maintaining sharpness over longer periods.

- For fine, detailed work like garnishing or carving, a hollow grind delivers precision, while a convex grind is better suited for heavy-duty slicing that demands durability.

Choosing the right grind helps you achieve cleaner cuts and reduces fatigue during intricate tasks.

Versatile Everyday Use

For everyday tasks, selecting the right knife grind depends on balancing ease of use, durability, and versatility. A flat grind is a solid choice because it handles a variety of chores like slicing, chopping, and general cutting with ease. It offers a good mix of strength and sharpness, making it suitable for kitchen work and outdoor tasks. Hollow grinds excel in precision slicing and light-duty tasks, thanks to their thin edges and low friction, though they’re less durable for heavy use. Convex grinds provide a balance by offering strength and smooth cutting, ideal for tasks that require both finesse and toughness, such as outdoor or camping chores. Each grind type brings unique benefits that can match your daily needs, depending on how you use your knife.

Heavy Duty Work

Heavy duty tasks demand knives that can withstand tough conditions and deliver reliable performance. Your choice of grind impacts how well your knife handles heavy work.

- Convex grind is ideal for chopping, splitting, and batoning, offering maximum strength, shock resistance, and durability. It’s perfect for outdoor, survival, or bushcraft tasks where impact is frequent.

- Flat grind provides a good balance of strength and cutting efficiency, suitable for general utility, heavy slicing, and chopping. Its robust edge supports tougher applications without sacrificing versatility.

- Hollow grind isn’t recommended here, as it’s less durable under shock and heavy impact. It’s better suited for precision tasks rather than heavy-duty work.

- Regular maintenance, especially on convex and flat grinds, ensures your knife maintains its edge during prolonged heavy use.

How Your Chopping and Slicing Feel Differently With Each Grind

The way your knife feels during chopping and slicing changes considerably based on its grind. With a hollow grind, you’ll notice a super smooth, effortless motion, thanks to its thin, low-friction edge. It glides easily through soft foods like fish or tomatoes, giving you precise control. A flat grind offers a balanced feel, making both push and pull cuts comfortable and predictable. It’s versatile enough for chopping and slicing a variety of ingredients. A convex grind provides a sturdy, powerful feel, especially when chopping harder items like wood or tough vegetables. The curved edge offers excellent support, reducing sticking and making slicing feel cleaner. Each grind influences not just the sharpness but also how much effort you need, shaping your overall cutting experience.

Common Mistakes and Myths About Knife Grinds

Many people hold misconceptions about knife grinds that can lead to poor choices or frustration. Here are some common mistakes and myths to clear up:

- Believing one grind suits all tasks. Different grinds excel in specific jobs, so choose based on your needs.

- Thinking hollow grinds are weak. While less durable for heavy chopping, they excel in slicing and precision, not all-around use.

- Assuming convex grinds are impossible to sharpen. They’re more challenging but not impossible—specialized stones or techniques help.

- Believing flat grinds are always better. They’re versatile but may not perform as well in heavy-duty chopping or shock resistance compared to convex grinds.

Understanding these myths helps you pick the right grind and avoid unnecessary frustration.

Choosing the Right Grind for Your Needs

Choosing the right grind depends on understanding your specific tasks and how each type performs. If you need precision slicing and easy sharpening, a hollow grind works well, especially for delicate cuts on fish or meat. For general use, everyday tasks, or kitchen work, a flat grind offers a versatile balance of strength and efficiency. If you require durability, shock resistance, or plan to do heavy chopping, a convex grind is your best choice, as it provides maximum support and edge retention. Consider how much maintenance you’re willing to do—hollows are easier to sharpen but less durable, while convex grinds need skill to maintain. Matching your needs with each grind’s strengths ensures better performance and longer-lasting cuts in your tools.

Frequently Asked Questions

Can You Convert a Hollow Grind Knife Into a Flat or Convex Grind?

You can convert a hollow grind knife into a flat or convex grind, but it requires skill and proper tools. To do this, you’ll need a whetstone, belt grinder, or sharpening system. Start by carefully reshaping the bevel, maintaining consistent angles. For a flat grind, flatten the hollow’s concave curve. For convex, gently round the edge. Practice patience, as improper technique can damage the blade or reduce its effectiveness.

How Does the Grind Affect the Knife’s Edge Retention Over Time?

Your knife’s grind shapes its edge retention like a fortress, either standing strong or crumbling quickly. Hollow grinds, with their thin edges, dull faster and chip easily under heavy use. Flat grinds hold their edge longer but need more frequent sharpening. Convex grinds, with their robust curvature, excel in durability, resisting chipping and maintaining sharpness longer, making them perfect for tough tasks. The grind directly influences how long your knife stays razor-sharp.

Are Certain Grinds Better for Specific Foods or Materials?

Certain grinds work better for specific foods or materials. Hollow grinds excel at slicing soft items like fish or meat because they create a thin, precise edge with low friction, giving you cleaner cuts. Flat grinds are versatile, suitable for chopping and general kitchen tasks. Convex grinds are best for tough, hard-duty work like chopping wood or outdoor tasks, offering durability and shock resistance for heavy materials.

Is It Possible to Sharpen All Grinds With the Same Tools?

Yes, you can sharpen all grinds with the same tools, but it takes skill and some adaptation. A sharpening stone or belt can work on hollow, flat, and convex edges, but convex blades need more careful, curved strokes or specialized equipment. Don’t worry if it’s tricky at first—practice makes perfect. With patience, you’ll maintain your knives’ sharpness no matter the grind, ensuring smooth, effective cuts every time.

How Do Grind Types Influence the Knife’s Overall Weight and Balance?

Your grind type affects your knife’s weight and balance markedly. Hollow grinds are lighter and more nimble due to their thin edges, making them feel agile. Flat grinds add some heft, providing a balanced feel suitable for general tasks. Convex grinds are usually the heaviest, offering stability and strength for heavy-duty work. Choosing a grind impacts how comfortable and controlled your knife feels during different tasks.

Conclusion

Choosing the right knife grind can dramatically improve your cutting experience. Did you know that hollow grinds are favored by 70% of professional chefs for their precise slicing? Whether you prefer the sharpness of a hollow grind, the versatility of a flat grind, or the strength of a convex edge, understanding these differences helps you pick what’s best for your tasks. Invest in the right grind, and you’ll enjoy better cuts and longer-lasting blades every time.