You should consider regrinding your knife when you notice visible cracks, chips, warping, or bends, as these can compromise safety and performance. If the edge feels dull despite frequent honing or your cuts are uneven and difficult, it’s a sign you need regrinding or sharpening. Handle damage or excessive wear also indicate it’s time for professional attention. Ignoring these signs risks injury and damage — keep an eye out for what’s coming next.

Key Takeaways

- The blade no longer responds to honing and remains dull despite repeated sharpening attempts.

- Visible edge deformation, such as rolled or rounded edges, indicates the need for regrinding.

- Cracks, chips, or significant nicks along the edge compromise safety and suggest regrinding or replacement.

- Dullness persists even after honing, signaling excessive steel wear requiring regrinding.

- Structural issues like warping or handle damage point to the need for regrinding or full replacement for safety.

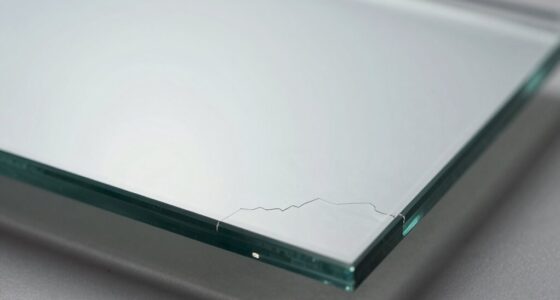

Visible Cracks and Structural Damage

Cracks near the bolster or along the spine are clear signs that your knife’s structural integrity is compromised. You should take these cracks seriously because they weaken the blade, making it unsafe to use. Deep cracks can cause unpredictable cuts and may lead to food contamination if the blade breaks during use. To spot these issues, inspect your knife closely under good lighting, looking for hairline fractures or visible splits. Remember, cracks can’t be repaired safely, so replacing the knife is the best course of action. Continuing to use a damaged knife increases the risk of injury and worsens the damage. When you notice cracks, don’t delay—safety always comes first, and a compromised blade needs immediate attention. Additionally, blade maintenance plays a crucial role in preventing such damage and extending the lifespan of your knife. Proper storage practices can also help minimize stress on the blade and reduce the chance of cracks forming over time. Regularly checking your knife’s structural integrity can help catch issues early before they become dangerous. Incorporating proper sharpening techniques can also help maintain blade strength and prevent weaknesses from developing over time.

Presence of Chips, Dents, or Nicks Along the Blade

Chips, dents, or nicks along your knife’s edge can greatly hinder your cutting performance. These imperfections often signal that your blade has experienced considerable wear or damage. Depending on their size and depth, they may be repairable or require full replacement to ensure safe, efficient use. Recognizing signs of blade deterioration is essential for maintaining optimal cutting performance and ensuring safety in the kitchen.

Impact on Cutting Performance

When your knife develops chips or dents along the edge, your cutting performance can suffer considerably. These imperfections create uneven contact with food, making slices less smooth and more difficult to control. Deep nicks can cause the blade to catch or snag, increasing the risk of slipping and potential injury. As chips grow, they can also break off during use, leaving jagged edges that further impair precision. This unevenness forces you to apply more pressure, which can lead to uneven cuts and faster blade dulling. Over time, damaged edges lose their sharpness quickly, requiring frequent honing or sharpening. If chips or dents persist, they compromise your efficiency in the kitchen and may signal that it’s time for regrinding or replacing the blade altogether.

Indication of Blade Wear

Detecting chips, dents, or nicks along your blade is essential for evaluating its wear. These imperfections often indicate that your knife has endured heavy use or accidental impact. Large or multiple chips can cause uneven cuts and snag on food, making prep less efficient. Deep nicks weaken the edge, increasing the risk of further damage and reducing sharpness. Gently run your finger along the edge to feel for irregularities; even small imperfections are signs of wear. Chips and nicks don’t just hinder performance—they can also compromise safety by causing unpredictable slips. If you notice these issues, it’s a clear sign your blade may need professional sharpening or regrinding, or possibly a full replacement if the damage is severe. Ignoring these signs can lead to faster deterioration and compromised safety.

Repair or Replacement Needed

If your knife has visible chips, dents, or nicks along the blade, it’s a clear sign that professional evaluation is needed. Large or multiple chips weaken the edge and make cutting uneven, increasing the risk of slipping or injury. Deep nicks can trap food particles and compromise hygiene. While small chips might be sharpened out, significant damage usually requires replacing the knife altogether. Dents and nicks also affect performance, making precision difficult and increasing fatigue during use. Carefully run your finger along the edge to feel for imperfections—if you notice rough spots or deep gouges, it’s time to consult a professional. Ignoring these signs can lead to further damage, unsafe handling, and compromised food safety, making knife replacement the safest choice. Regular maintenance and understanding blade damage, such as chips and dents, can help extend the life of your knives and ensure safety during use. Recognizing damage early can also prevent costly repairs and improve overall safety. Additionally, examining the coating integrity of the blade can reveal underlying issues that may require more extensive intervention.

Warping or Bending of the Blade

A warped or bent blade can considerably impair your knife’s performance, making it difficult to achieve precise cuts. When your knife no longer aligns properly with the cutting surface, control and accuracy suffer. You might notice the blade twists or curves when you hold it up to the light. This deformation can cause uneven slicing and increased effort during use. Additionally, structural issues like warping may be a sign that the blade has experienced an impact or temperature stress, which can compromise its material integrity. Proper blade maintenance can help prevent warping and extend the lifespan of your knife. Recognizing early signs of warping can help you address issues before they lead to permanent damage or safety concerns. Monitoring for signs of structural instability is essential to ensure your knife remains safe and effective.

Edge Rounding, Rolled Edges, or Loss of Taper

When your knife’s edge becomes rounded or develops rolled edges, you’ll notice it no longer slices cleanly. This deformation reduces cutting precision and dulls the blade faster, making your work more effortful. Recognizing these signs early helps determine if regrinding can restore performance or if it’s time to replace the knife. Additionally, understanding the fabric composition used in your knife’s material can influence how well it holds an edge over time. Proper blade maintenance techniques can also prolong the sharpness and overall lifespan of your knife, especially when considering the material durability associated with different blade steels. Being aware of edge retention properties specific to your knife’s steel can help you better decide when to regrind or replace it.

Dulling Cutting Performance

Over time, repeated sharpening can cause the knife’s edge to become rounded or rolled, diminishing its ability to cut efficiently. When this happens, you’ll notice that slices are less clean, and the knife requires more force. The taper that once created a fine, precise cut begins to flatten or disappear, making the blade less effective. You might also see visible signs like a dull, uneven edge or a lack of sharpness after honing. Free Floating can also contribute to inconsistent edge wear, further emphasizing the need for regrinding. These signs mean your knife is losing its original geometry, and regrinding can help restore its performance.

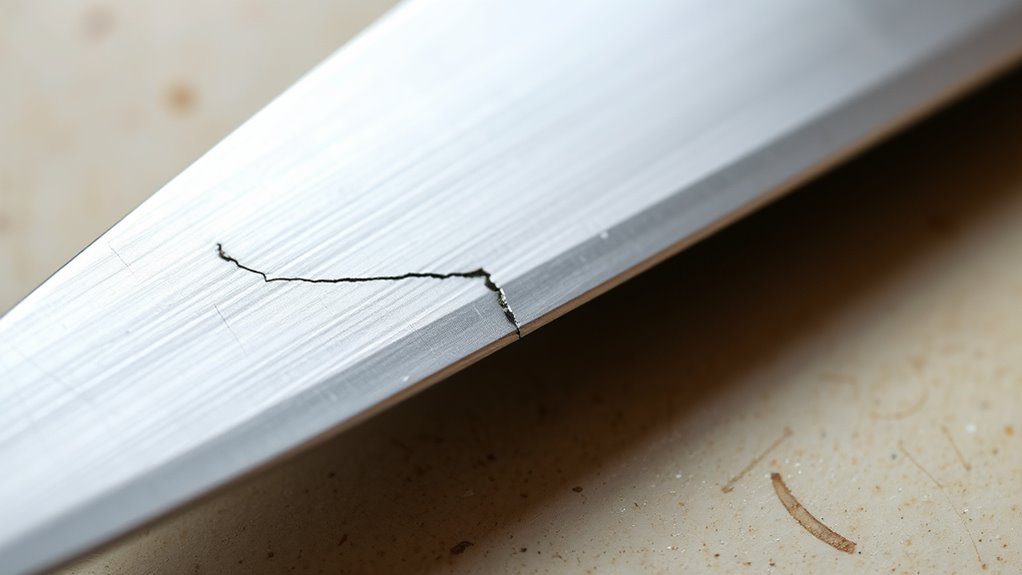

Visible Edge Deformation

Repeated sharpening can cause the knife’s edge to become rounded, rolled, or lose its taper, making it less effective. As steel wears down, the sharp, tapered profile diminishes, leading to a duller cutting surface. You might notice the edge looks blunted or asymmetrical under inspection. Rolled edges appear as tiny bulges along the edge, which can catch on food or tear rather than slice smoothly. Loss of taper reduces the knife’s ability to cut with precision, resulting in uneven slices and increased effort. These visible deformations indicate the steel has been overworked, and further sharpening won’t restore the original geometry. Recognizing these visual cues early can help prevent further damage and extend the life of your blade. Additionally, understanding the steel composition of your knife can influence how often regrinding is necessary, as some steels are more resistant to deformation than others. When you see these signs, it’s time to evaluate regrinding or replacing the knife to attain optimal performance.

Reduced Slicing Precision

As steel wears down from frequent sharpening, your knife’s edge can become rounded, rolled, or lose its original taper, substantially reducing slicing accuracy. This deterioration compromises your control and results in uneven cuts. You might notice that slices are less clean, or you need more effort to cut through ingredients. Over time, the edge’s shape changes, diminishing its ability to perform precise work.

- Rounded or rolled edges that feel dull or blunt

- Loss of taper leading to uneven cuts

- Increased force required during slicing

- Visible flattened or thickened edge on inspection

- Reduced responsiveness, causing rough or torn cuts

Handle Cracks, Wobbles, or Damage

If your knife handle feels loose, cracked, or wobbly, it’s a clear sign that it’s time to consider regrinding or replacing the blade. A damaged handle compromises your grip and safety, increasing the risk of slips and accidents. Cracks in the handle weaken the overall structure, making the knife less reliable during use. Wobbly handles often indicate worn or loose fittings that can’t be securely fixed. These issues affect your control and precision, making tasks more difficult and unsafe. Ignoring handle damage can lead to further deterioration or injury. If you notice any cracks, looseness, or wobbling, prioritize safety by replacing the handle or the entire knife. A secure, intact handle ensures better performance and peace of mind during food prep. Additionally, understanding layer concepts in your tools can help you identify underlying structural issues that might contribute to handle instability. Recognizing wear patterns can also guide you in timely regrinding or maintenance to extend your knife’s lifespan. Regular inspections, along with knowledge of material composition, can help prevent future damage and ensure safe use. Moreover, paying attention to proper storage can minimize unnecessary stress on the handle and prolong its life. Incorporating visual cues from routine checks can alert you to early signs of damage before they become serious.

Rust Spots, Corrosion, or Discoloration

Rust spots, corrosion, or discoloration on your knife are clear signs that it’s time to contemplate replacing the blade. These issues weaken the steel, making your knife less safe and less effective. Rust can hide deep within the metal, leading to structural failure, while discoloration often indicates material breakdown. Ignoring these signs risks food contamination and reduces cutting performance. Consider these points:

- Rust spots that won’t scrub off with cleaning

- Visible corrosion that penetrates the blade surface

- Discoloration that doesn’t respond to polishing

- Pitting or surface roughness from corrosion

- Deep staining indicating material degradation

If you notice any of these, your knife’s integrity is compromised, and regrinding might not be enough. Material breakdown can suggest that the steel has deteriorated beyond simple sharpening. Upgrading to a rust-resistant steel or replacing the blade ensures safety and superior performance. Quality assessment can help determine whether regrinding will suffice or if replacement is the better option.

Dullness Despite Frequent Honing

Repeated honing can keep your knife’s edge appearing sharp, but it doesn’t always restore true cutting performance. If your knife feels dull despite frequent honing, it’s a sign the blade has worn beyond simple maintenance. Honing realigns the edge but doesn’t remove material; over time, the steel can become too thin or rounded, reducing its ability to cut cleanly. You might notice increased effort needed to slice through ingredients or uneven cuts despite regular honing sessions. When honing no longer improves performance, it indicates the edge has deformed or lost its original profile. In such cases, regrinding or sharpening becomes necessary. Ignoring persistent dullness can lead to more blade damage or compromised safety, making it essential to evaluate whether your knife needs professional regrinding or replacement.

Uneven or Difficult Cutting Performance

When your knife starts cutting unevenly or feels unusually tough to push through ingredients, it’s a clear sign that the blade’s edge isn’t performing properly. You may notice more resistance, jagged slices, or inconsistent results. These issues often stem from a dull or deformed edge that no longer glides smoothly. To diagnose, check for:

A dull or deformed knife edge causes uneven cuts, resistance, and tearing—time to regrind for smooth, safe slicing.

- Increased force needed to cut

- Irregular or jagged edges on slices

- Food tearing instead of clean cuts

- Edges catching or snagging on ingredients

- Inconsistent thickness in slices

If you experience these signs, it’s time to contemplate regrinding. Ignoring uneven performance can lead to further damage and compromise your safety and efficiency in the kitchen. Proper regrinding restores sharpness and smooth operation.

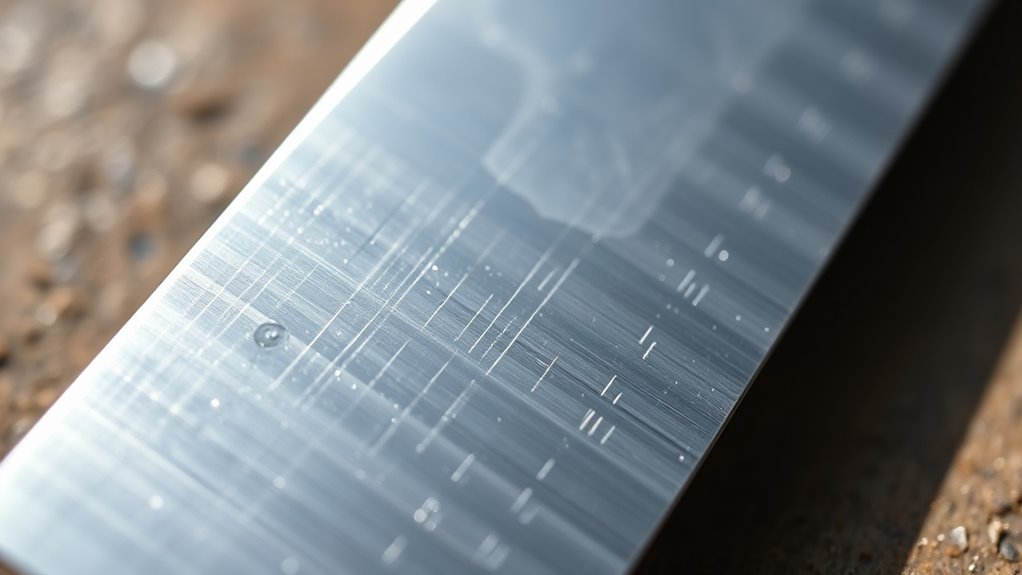

Signs of Steel Wear or Thinning Edges

Steel wear or thinning edges often become noticeable through subtle changes in your knife’s performance. You might find it takes more effort to cut through foods or that slices aren’t as clean as before. When you run your finger lightly along the edge, you may feel a rounded or dull profile instead of a sharp taper. These signs indicate the steel is wearing down and the edge is thinning. Over time, repeated sharpening can cause the blade to lose its original geometry, reducing effectiveness. If you notice the edge seems less refined or it struggles to pierce or slice smoothly, it’s a clear sign the steel is worn. Addressing these signs early by regrinding can restore the blade’s shape and prolong its usefulness. Maintaining a sharp edge can help prevent premature wear and extend your knife’s lifespan.

Repeated Repairs or Professional Assessments

If your knife requires multiple repairs or frequent professional assessments, it’s a clear sign that regrinding may no longer be effective. Constant repairs suggest the steel has worn below ideal edge retention, making further sharpening futile. You might notice repeated honing that doesn’t restore sharpness or the blade needing adjustments every few weeks.

Repeated repairs and honing failures indicate your knife’s edge is beyond saving.

Consider these indicators:

- Regular visits to a professional for minor fixes

- Repeated sharpening with minimal results

- Persistent issues with edge stability

- Continuous repair costs outweigh replacement value

- Frustration with performance despite maintenance

If you find yourself repeatedly seeking repairs, it’s time to evaluate whether your knife’s structural integrity is compromised. Continuing repairs may only delay the inevitable, and replacement could be the safer, more efficient choice.

Frequently Asked Questions

Can Minor Chips Be Sharpened or Repaired?

Minor chips can sometimes be sharpened out, but it depends on their size and depth. If the chips are small and shallow, you might be able to smooth them with careful honing or sharpening. However, deep or multiple chips usually require professional repair or replacement, as trying to fix them yourself might damage the blade further or compromise its safety. Always inspect carefully before attempting to repair minor chips.

How Do I Differentiate Between a Bend and a Warp?

You can tell the difference between a bend and a warp by inspecting the blade closely. Hold the knife up to a light and check for a gentle curve or twist; a bend usually causes a noticeable curve, while warp might make the blade appear twisted or uneven when viewed from the side. Wobbling or misalignment during use also indicates warping, which affects control, while bending often results in a more pronounced, consistent curve.

Is Surface Rust Always Unsafe for Food Preparation?

Surface rust isn’t always unsafe for food prep, but it depends on its severity. Light rust can often be removed with thorough cleaning and polishing. However, if rust has penetrated deeply or caused pitting, it can harbor bacteria and weaken the steel, making your knife unsafe. Always inspect carefully—if rust persists after cleaning or if the blade shows signs of corrosion damage, it’s safer to replace the knife.

When Is a Handle Crack Serious Enough to Replace?

If your handle has cracks that are deep, spreading, or cause wobbling, it’s time to replace the knife. Serious cracks compromise grip safety, increasing the risk of slips during use. Also, if the cracks are near the handle’s base or extend into the material, they weaken the entire structure. Don’t ignore handle damage—prioritize safety and control by replacing the knife before it becomes hazardous.

How Often Should I Regrind My Knife for Optimal Performance?

You should regrind your knife every 6 to 12 months, depending on how often you use it. Regular sharpening helps maintain a sharp edge and prevents dullness. If your knife starts to feel less responsive or you notice nicks or rolls, it’s time to regrind sooner. Always pay attention to performance; a dull or damaged edge indicates it’s time for maintenance to keep your knife in top shape.

Conclusion

If your knife shows cracks, chips, warping, or just won’t cut smoothly despite honing, it’s time to regrind. Ignoring these signs can compromise safety and damage your blade further. Don’t wait until a small flaw becomes a big problem—trust your senses and inspect regularly. After all, isn’t a sharp, reliable knife worth the effort? Keep your blades in top shape and enjoy safer, more precise cuts every time.