When you get a new knife, it feels incredibly sharp because of its pristine surface finish and precisely ground edge. But that sensation can fade quickly as microscopic damage, surface wear, and tiny microfractures develop from everyday use, dulling the edge. Factors like cutting materials, technique, and proper maintenance impact how fast your knife dulls. If you want to understand the real reasons behind this and how to keep that sharp feeling longer, keep exploring further.

Key Takeaways

- New knives often feel sharp due to their pristine surface finish and precise edge geometry, enhancing initial cutting sensation.

- The perceived sharpness diminishes quickly because surface residues, microscopic imperfections, and dull spots develop with use.

- Sensory adaptation causes your tactile perception to lessen, making the edge seem duller even if it remains sharp physically.

- Regular microstructural changes, like tiny cracks and wear, reduce actual edge sharpness over time, affecting performance.

- Proper maintenance, like honing and sharpening, restores the edge, but neglect accelerates dulling and diminishes the initial sharp feel.

The Initial Appeal of a Brand-New Blade

When you first pick up a brand-new knife, it immediately feels sharp and precise, drawing you in with its clean edge. The blade aesthetics play a big role here, as the sleek, polished surface catches your eye and sparks excitement. The way the light reflects off the smooth, flawless finish makes the knife seem perfectly crafted, heightening your anticipation. Packaging design also influences your initial impression; a well-presented box or sleeve suggests quality and care, enhancing the knife’s allure. These visual cues create a sense of freshness and perfection, making you enthusiastic to test its capabilities. That initial feeling of sharpness is as much about presentation as it is about the actual blade, setting high expectations from the start. Premium craftsmanship in knife manufacturing enhances this perception of quality and sharpness, even if the actual cutting edge may need some breaking in. Additionally, the perception of sharpness can be influenced by visual factors, which can sometimes be misleading regarding the true edge quality. Recognizing the importance of perceived sharpness can help you better understand when a knife truly needs sharpening versus just a visual impression. Being aware of initial impressions can also help prevent premature sharpening and extend the life of your blade. Understanding the role of visual attributes can help you differentiate between a truly sharp edge and an illusion created by surface finish.

How Manufacturing Processes Influence Sharpness

The way a knife is manufactured directly affects how precisely it cuts and how smooth its finish feels. High-quality materials and careful finishing processes create sharper edges that stay effective longer. When manufacturing is done well, your knife performs better right out of the box. Additionally, packing & organization techniques can help maintain the knife’s sharpness by reducing unnecessary handling and potential damage during storage. Proper storage methods, such as using protective sheaths or knife blocks, also play a crucial role in preserving the sharp edge over time by minimizing damage from impact and corrosion. Employing manufacturing standards ensures consistent quality and longevity of your knives, especially when considering the importance of material selection in durability and performance. Furthermore, adherence to strict quality control procedures during production can significantly influence the overall sharpness and reliability of the final product.

Precision of Blade Cutting

Manufacturing processes play a crucial role in determining how sharp a knife’s blade can become. Precision in cutting depends on how well the blade’s edges are finished and aligned during production. Techniques like honing and grinding ensure the edge is finely sharpened, directly impacting performance. Additionally, blade ergonomics and handle design influence how you apply force and control during cutting, affecting the overall effectiveness. A well-designed handle allows for better grip and stability, ensuring consistent pressure along the blade. When these manufacturing details are carefully managed, the knife maintains its sharpness longer and cuts more precisely. Proper manufacturing and thoughtful design are key to maximizing cutting precision and prolonging blade sharpness.

Quality of Material Finish

Achieving a sharp edge isn’t just about how well the blade is honed; it also depends on the quality of the material finish created during manufacturing. A smooth, consistent finish enhances blade aesthetics, making the knife look sharper and more refined. High-quality finishes reduce microscopic imperfections that can dull edges over time. Additionally, manufacturing processes that focus on precision improve handle ergonomics, ensuring comfortable, secure grip, which helps maintain control during use. When the material finish is flawless, it minimizes friction and prevents early wear, keeping the knife feeling sharp longer. Conversely, poor finishes can leave rough spots that cause uneven wear and reduce cutting performance. Overall, the material finish plays a crucial role in both the appearance and longevity of your knife’s sharpness.

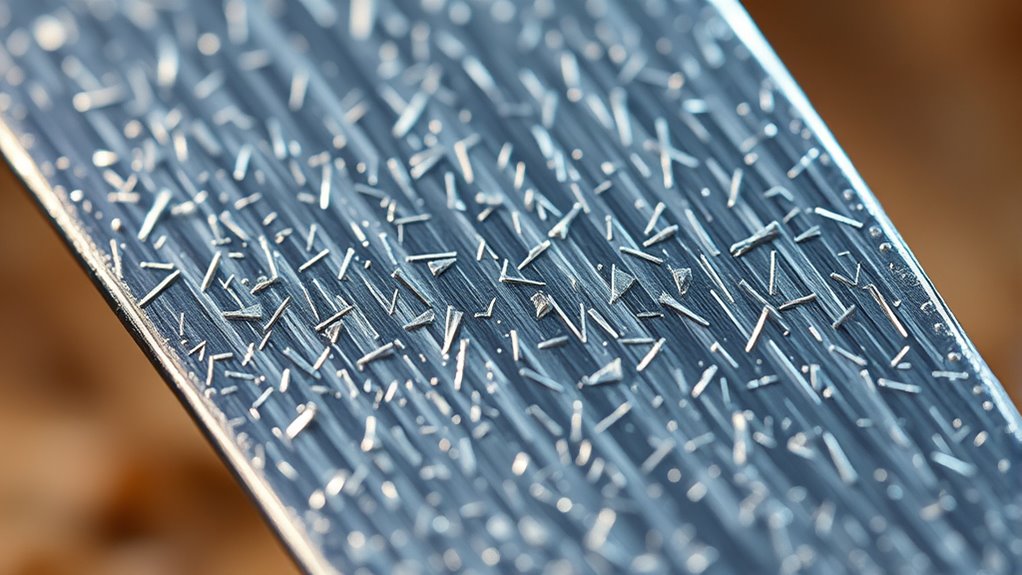

The Microstructure of a Sharp Edge

Because the microstructure of a knife’s edge determines its sharpness, understanding how tiny grains and phases align at this scale is essential. When a blade is newly sharpened, its microstructure is compact, with minimal edge microfractures, allowing for a clean, precise cutting surface. Over time, microstructure evolution occurs as stresses cause tiny cracks and dislocations to form at the atomic level. These edge microfractures weaken the structure, reducing sharpness and making the knife feel duller. The arrangement of carbides, grain boundaries, and phases influences how well the microstructure resists wear and damage. A stable, refined microstructure helps maintain edge integrity longer, while microfractures accelerate dulling. Recognizing this microscopic foundation explains why new knives feel sharp and how their microstructure impacts longevity. Understanding microstructure provides insight into how and why blades dull over time. Additionally, factors such as microstructure stability can be affected by use and maintenance, impacting the lifespan of the edge. The grain boundary characteristics also play a critical role in resisting microfracture formation and maintaining sharpness over repeated use.

The Role of Surface Finish and Polish

The microstructure of a knife’s edge provides a solid foundation for its sharpness, but surface finish and polish influence how that sharpness feels during use. A well-polished blade not only enhances blade aesthetics but also reduces friction, making cutting smoother. Different polishing techniques, from fine stones to abrasive pastes, create varied finishes impacting performance. Consider this table:

| Finish Level | Blade Aesthetics | Cutting Feel |

|---|---|---|

| Coarse | Basic appearance | Rough, less efficient |

| Medium | Slight shine | Moderate smoothness |

| Fine | Mirror-like shine | Very smooth, sharp |

| Ultra-fine | High gloss | Maximum comfort |

Choosing the right polish affects both the look and the feel, helping your knife perform at its best. Additionally, paying attention to surface finish can prevent premature dulling and extend the lifespan of your blade.

Understanding the Edge Geometry and Angles

Understanding the edge geometry and angles is essential to maximizing a knife’s sharpness and performance. The way your knife’s edge is shaped and the specific edge angles influence how well it cuts and how durable it remains.

To optimize your knife, consider these key points:

- Edge angles determine the sharpness; a smaller angle (around 15°-20°) offers a sharper edge but may be less durable.

- Grind geometry affects how the blade distributes force; a thinner grind enhances slicing but can weaken the edge.

- The overall edge geometry impacts how the knife interacts with materials, influencing cutting efficiency and longevity.

Understanding these factors helps you choose or maintain the right edge for your needs.

Factors That Cause Dulling Over Time

Even if your knife starts out with a finely honed edge, daily use and wear can cause it to dull over time. Factors like blade ergonomics influence how evenly your knife contacts surfaces, affecting how quickly it dulls. A poorly designed blade may require more force, increasing edge wear. Handle materials also play a role; rough or hard handles can cause additional pressure or vibrations, accelerating dulling. Conversely, comfortable, well-balanced handles reduce strain, helping maintain sharpness longer. Frequent cutting on hard surfaces or with improper technique can bend or chip the edge, speeding up dulling. Over time, these factors, combined with natural wear, diminish your knife’s initial sharpness, making it less effective and requiring more frequent sharpening.

The Impact of Cutting Materials and Techniques

Using the wrong cutting technique or applying excessive force can quickly dull your knives, regardless of their initial sharpness. The material you’re cutting and your user handling play vital roles in maintaining blade sharpness. Hard or abrasive surfaces, like frozen foods or bone, can chip or dull the edge faster. Proper technique involves slicing smoothly rather than pressing down, which preserves blade ergonomics and reduces stress on the edge. Additionally, the type of material impacts the blade’s lifespan—softer foods like fruits are gentler, while dense meats are harsher. To keep your knives sharp longer, focus on light, controlled cuts and ensure your handling aligns with the knife’s design. This approach minimizes unnecessary wear and maintains cutting efficiency. Using appropriate cutting surfaces also helps prevent blade damage and prolongs sharpness. Being mindful of cutting surface material can make a significant difference in preserving your knife’s edge over time, especially when considering blade maintenance practices that support longevity.

Why Your Perception of Sharpness Changes

You might notice your sense of sharpness shifting over time, even with the same knife. Sensory adaptation can make a knife feel less sharp after repeated cuts, while surface conditions like dullness or residue can alter your perception. Understanding these factors helps explain why a knife’s edge seems to change in your hands. Additionally, ambient environmental factors such as humidity and temperature can influence the way your senses perceive sharpness, further contributing to the fluctuation. For example, changes in moisture levels can affect how well a blade interacts with food, impacting perceived sharpness. Variations in light conditions can also influence how sharply you perceive the edge, as shadows and glare alter visual cues. Moreover, blade maintenance practices like honing and sharpening play a crucial role in maintaining consistent sharpness over time. Recognizing how sensory perception adapts helps you better understand these fluctuations and manage your expectations when using knives.

Sensory Adaptation Effects

When you first handle a new knife, its sharpness feels obvious and intense, but your perception quickly diminishes due to sensory adaptation. Your senses become less responsive to the sensation over time, making the knife seem duller even if it remains sharp. This effect explains why the initial excitement from a sleek, well-designed knife fades fast.

Consider these points:

- Your brain filters out constant stimuli, reducing the perceived sharpness.

- Knife aesthetics influence first impressions, but sensory adaptation can diminish that perception.

- Marketers often emphasize sharpness to appeal to consumers, yet sensory adaptation means the true experience may not match initial impressions.

Understanding this helps you recognize why your perception shifts, despite the knife’s actual condition.

Surface Condition Impact

The surface condition of a knife plays a significant role in how sharp it feels, as imperfections or dulling factors can diminish your perception of its edge. Even minor scratches, dull spots, or dulling residues can make a sharp blade seem less effective. Blade aesthetics, such as shiny finishes or smooth surfaces, often influence how sharp you think a knife is, but these visual cues aren’t always accurate. Marketing hype can emphasize “brand-new” sharpness, glossing over surface imperfections that develop quickly with use. Over time, these surface flaws disrupt your tactile feedback, making the edge feel duller—even if the actual sharpness remains unchanged. Recognizing that surface condition impacts perception helps you understand why your new knife might not feel as sharp after some use. Additionally, surface integrity can be affected by cleaning methods or storage conditions, which may accelerate dulling or surface damage.

Tips to Maintain and Restore Sharpness

Maintaining and restoring your knife’s sharpness is essential for safe and efficient use. To keep your blade aesthetics appealing and handle ergonomics comfortable, follow these tips:

- Regular honing with a honing steel realigns the edge, keeping it sharp without removing material.

- Use proper sharpening tools, like a whetstone or sharpening system, to restore dull edges. Maintain a consistent angle for *ideal* results.

- Clean and dry your knife after use to prevent corrosion, which can dull the blade and affect handle comfort. Proper maintenance preserves both the knife’s appearance and functionality.

Frequently Asked Questions

Can Environmental Factors Affect a Knife’s Sharpness Over Time?

Environmental factors definitely affect your knife’s sharpness over time. Poor storage conditions, like leaving it in a humid place, can lead to blade oxidation, which dulls the edge. Exposure to moisture and temperature changes also accelerate corrosion. To keep your knife sharp longer, store it in a dry, stable environment and clean it regularly. Proper care prevents oxidation and helps maintain that sharp, precise edge you depend on.

How Does Honing Differ From Sharpening in Maintaining Blade Sharpness?

Honing and sharpening differ markedly: honing realigns the blade’s edge, restoring sharpness without removing metal, while sharpening grinds away dull material. Did you know that 75% of home cooks prefer honing for routine maintenance? Your knife’s blade flexibility and handle ergonomics influence how effectively honing restores sharpness, ensuring safer, more precise cuts. Regular honing keeps your knife performing well, but sharpening is necessary when the edge becomes visibly dull.

What Role Does Steel Type Play in Edge Retention?

Steel type greatly influences edge retention because of its composition and alloy hardness. Harder alloys, like high-carbon steels, hold an edge longer but can be more brittle. Softer steels may sharpen easily but dull faster. When choosing a knife, consider the steel’s composition to match your cutting needs, balancing hardness for durability with flexibility to prevent chipping. Proper maintenance guarantees your knife stays sharp longer, regardless of steel type.

Why Do Some Knives Seem to Stay Sharp Longer Than Others?

Imagine your knife is a marathon runner; some train harder, others slack off. Knives that stay sharp longer are often well-maintained and used with proper cutting techniques. Regular blade maintenance, like honing and sharpening, keeps the edge intact. Using correct cutting methods reduces stress and wear. So, treat your knife like a champion—respect its needs, practice good technique, and it’ll stay sharp through every cut.

How Often Should I Properly Sharpen My Knives?

You should sharpen your knives every 6 to 12 months, depending on how often you use them. Regular knife maintenance keeps them performing their best. Use quality sharpening tools like a whetstone or honing rod to maintain your blades’ edge. If you notice your knives aren’t cutting as smoothly, it’s time to hone. Proper maintenance ensures longevity and safety, so don’t wait until they feel dull to give them some attention.

Conclusion

So, next time your shiny new knife loses its edge faster than your patience, remember it’s not just in your head—or your lack of skill. That “sharp” feeling is a fleeting illusion, crafted by microstructures and surface finishes. With a little know-how, you can fool your senses and keep that blade feeling like a samurai’s sword. Just don’t blame your tools if they betray you—after all, they’re just doing what knives do best: dulling with style.