To tell patina from rust on carbon steel, look at the surface appearance—patina appears smooth, matte, and uniformly colored in bluish or greenish hues, while rust is rough, flaky, and reddish-brown with uneven patches. Patina often stays stable and resists further corrosion, whereas rust shows signs of active deterioration and damage. Examining texture, color layers, and response to cleaning helps you distinguish them. Continue exploring to uncover more details about their differences.

Key Takeaways

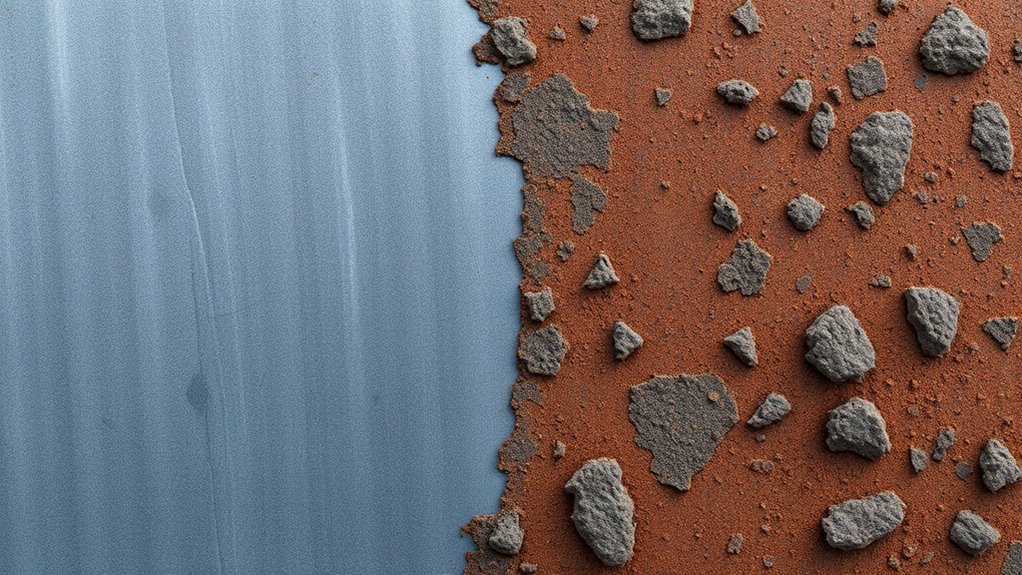

- Patina appears as a smooth, matte, bluish or greenish layer, while rust is rough, flaky, and reddish-brown.

- Patina is uniform and stable, whereas rust shows irregular patches, discoloration, and peeling.

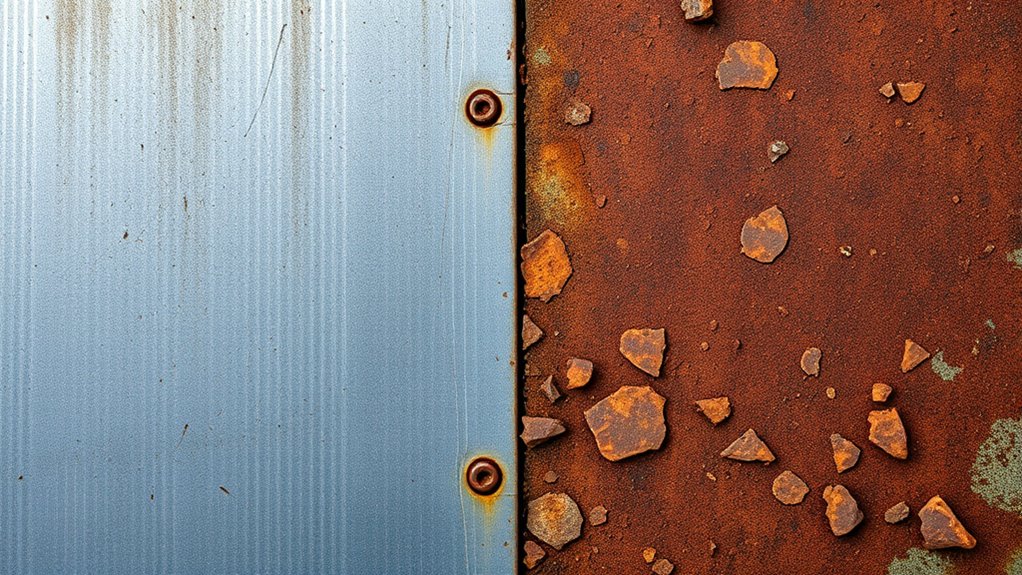

- Patina feels smooth or velvety; rust is rough, flaky, and abrasive to touch.

- Cleaning reveals patina’s consistent color; rust may chip, crumble, or reveal shiny metal underneath.

- Patina indicates protection and stability; rust signals active corrosion and potential structural damage.

Visual Differences in Surface Appearance

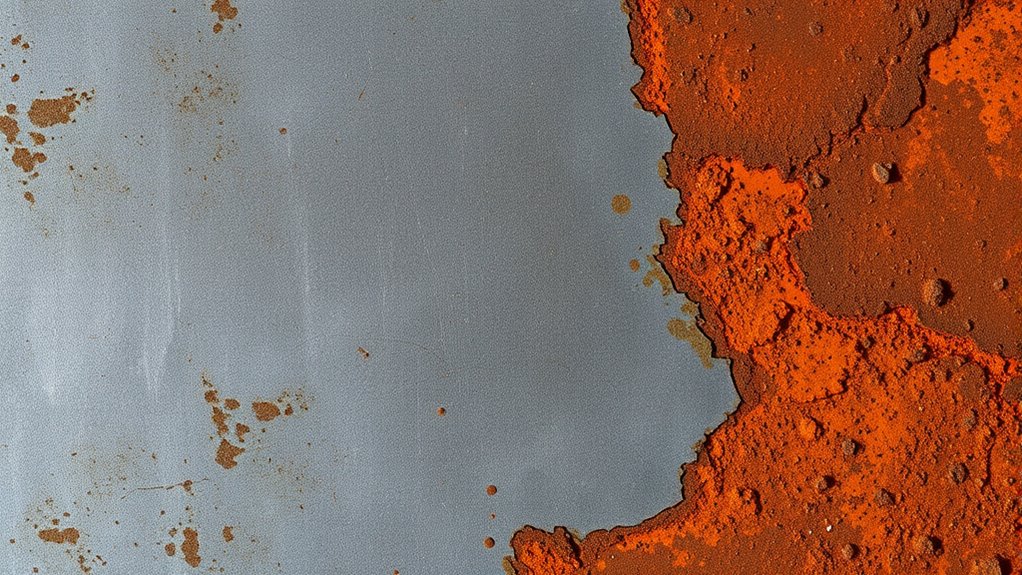

While patina and rust both change the surface of metals, they look quite different. Patina often creates a smooth, matte surface with a subtle sheen that reflects light gently, giving it an aged but intentional appearance. Rust, on the other hand, usually results in a rough, flaky texture with a dull, uneven surface. You’ll notice edge discoloration more prominently with rust, as it tends to spread from the edges inward, creating a distinct, irregular border. Patina generally forms uniformly across the surface, maintaining a consistent tone and sheen. Rust’s surface appears uneven and flaky, with layers peeling away. These visual clues help you quickly distinguish between the protective, aesthetic patina and the corrosive, damaging rust. Additionally, surface appearance can serve as a quick visual indicator of whether the metal has been intentionally treated or is suffering from corrosion. Recognizing metal surface conditions is essential for proper maintenance and preservation of carbon steel objects. Understanding the oxidation process can further aid in identifying whether a surface has developed a natural patina or has been compromised by rust. Environmental factors like moisture and pollutants greatly influence the formation of rust, making awareness of surroundings crucial for metal care.

Color Variations and Shades

You’ll notice that patina and rust display different color palettes, ranging from warm browns and greens to vibrant blues. Shade intensity can vary based on exposure and age, giving each piece a unique look. As materials age, their colors shift, showing how time influences their overall appearance. Color evolution plays a key role in distinguishing these surface changes over years of exposure. Additionally, understanding the oxidation process helps explain how these color variations develop and deepen over time. Recognizing the surface chemistry behind these changes can provide further insight into their formation and longevity. Moreover, the environmental factors such as humidity and pollutants significantly impact how quickly and vividly these colors develop.

Color Palette Differences

Patina and rust each develop distinct color palettes that influence their visual appeal. The oxidation process causes patina to form gentle, often bluish or greenish hues, resulting in subtle surface coloration that adds character. Rust, on the other hand, produces rougher, reddish-brown shades due to iron oxide buildup. To tell them apart:

- Patina features smooth, often bluish-green or blackish tones.

- Rust displays coarse, reddish-brown or orange hues.

- Patina’s surface coloration tends to be more uniform and layered.

- Rust’s color varies with oxidation intensity, appearing more uneven and flaky.

- Color palette differences can help you quickly identify whether you’re dealing with a protective patina or corrosive rust, based solely on surface coloration.

Shade Intensity Variations

The intensity of color shades in patina and rust can vary widely, revealing important clues about their formation and health. You’ll notice that patina often exhibits more uniform color shades, with consistent hues across the surface. This uniformity indicates a stable, well-developed layer that forms slowly over time. In contrast, rust tends to display uneven shade intensity, with darker patches and irregular color variations, suggesting ongoing corrosion. Surface smoothness also plays a role: patina generally feels smoother and more polished, while rust can be rough and flaky. These differences in shade intensity and surface texture help you distinguish a protective, mature patina from active rust, which signals ongoing deterioration. Recognizing these variations allows for better assessment of the metal’s condition.

Age-Related Color Changes

As metal ages, its surface colors often shift, reflecting changes in chemical composition and environmental exposure over time. During the oxidation process, surface aging causes color variations that can help distinguish patina from rust. Here are some key points:

- Light, golden hues often indicate early oxidation, typical of initial surface aging.

- Darker brown or black shades suggest ongoing oxidation, forming protective layers.

- Blue or purple tints may appear, especially in steel exposed to specific environmental conditions.

- Bright, uneven patches usually signal rust formation, characterized by flaky, corrosive surface changes.

Understanding these age-related color changes helps you identify whether you’re dealing with a stable patina or active rust, based on how surface aging influences color variations over time.

Texture and Feel of the Surface

While rust often feels rough, flaky, and uneven to the touch, patina typically develops into a smoother, more unified surface. You’ll notice a change in surface roughness, with patina feeling velvety or slightly oily, providing a gentle tactile sensation. Rust, on the other hand, creates a gritty, abrasive texture that can chip or crumble under your fingers. The tactile sensation of patina is more consistent, almost like a natural film that coats the metal, whereas rust’s uneven buildup results in a coarse, irregular feel. This difference in texture is a clear indicator: patina offers a polished, refined surface, while rust feels coarse and unstable. Paying attention to these surface qualities helps you distinguish between the two coatings effectively. Additionally, understanding the surface condition assessment can help you determine the severity of corrosion, which is crucial for proper maintenance and preservation of valuable items. Incorporating surface condition assessment into your routine can further aid in identifying early signs of deterioration and help plan appropriate preservation strategies.

Location and Pattern of Discoloration

Discoloration patterns can reveal whether you’re dealing with patina or rust. Patina typically forms in even, smooth layers, often covering broad areas with consistent oxidation patterns. Rust, however, appears in irregular patches, with discoloration locations that are uneven and flaky. Additionally, Gold IRA markets tend to remain unaffected by these surface changes, highlighting the importance of proper metal identification. Recognizing these patterns can help prevent misinterpretation and ensure accurate assessment of metal condition, especially considering corrosion types and their implications. Examining oxidation characteristics can further assist in distinguishing between the two types of surface changes. Moreover, understanding the metallurgical processes involved in oxidation can provide deeper insight into whether the surface alteration is benign or indicative of deterioration. Observing the surface texture can also aid in differentiating patina from rust, as patina generally retains a smooth appearance compared to the roughness of rust patches.

Response to Cleaning and Scrubbing

When you clean or scrub patina and rust, your actions can change their appearance considerably. Scrubbing may remove surface layers, revealing different colors or textures underneath. Carefully considering your cleaning methods helps protect the integrity and character of the metal. Proper maintenance techniques are essential to preserve the metal’s natural look and prevent unnecessary damage. Additionally, understanding the metal’s composition can guide you toward appropriate cleaning practices that avoid harming the surface. Recognizing the types of corrosion common on carbon steel can also inform your approach to maintenance and help you identify whether you are dealing with patina or rust. Being aware of piercing aftercare practices can also offer insights into proper cleaning and handling of delicate surfaces, ensuring longevity and protection of the metal. Incorporating protective coatings can further help maintain the desired appearance and prevent deterioration over time.

Cleaning Impacts Appearance

Cleaning and scrubbing can substantially change the appearance of patina and rust, often in different ways. Your choice of polishing techniques and cleaning solutions influences the final look.

- Using abrasive cleaning solutions can remove delicate patina, exposing shiny metal underneath or dulling the surface.

- Gentle cleaning methods preserve the natural color but may leave rust spots untouched.

- Applying specific polishing techniques can enhance patina’s depth or remove rust stains without damaging the surface.

- Overzealous scrubbing risks stripping protective layers, making the metal more vulnerable.

- Considering the environment and the natural balance of the backyard can influence the choice of cleaning methods for natural pools and other outdoor features.

- Being mindful of environmental factors can also help maintain the integrity of outdoor finishes, preventing unwanted corrosion or deterioration.

- Understanding the chemical composition of cleaning products can help in choosing the right method to protect both patina and rust.

Scrubbing Reveals Layers

Scrubbing can intentionally or unintentionally uncover hidden layers beneath the surface of metal, revealing the complex history of corrosion and treatment. When you scrub, you might expose metal staining that wasn’t visible before, offering clues about previous exposure or protective coatings. Surface etching from aggressive cleaning can also reveal different layers of the metal’s surface, showing variations in patina or rust. These layers tell a story—whether they’re remnants of a controlled patina or signs of ongoing rust formation. By carefully scrubbing, you can distinguish between superficial corrosion and deeper, more persistent damage. Recognizing these layers helps you understand the metal’s condition and decide whether cleaning has revealed genuine patina or just surface rust.

Impact of Moisture and Humidity

Moisture and humidity play a crucial role in the development of rust and patina on metal surfaces. When moisture accumulates, it accelerates oxidation, leading to rust formation. Humidity effects are especially noticeable in environments with high moisture levels, which can cause rapid corrosion. To understand this better:

Moisture and humidity significantly accelerate rust formation and uneven patina development on metal surfaces.

- Increased moisture levels promote moisture accumulation on the surface.

- High humidity speeds up the oxidation process, fostering rust.

- Variations in humidity can cause uneven patina development.

- Persistent exposure to moisture prevents the formation of a stable patina, instead encouraging rust.

Chemical Reactions and Ph Levels

Chemical reactions driven by pH levels determine whether metal surfaces develop a protective patina or succumb to rust. The pH level influence plays a pivotal role in chemical corrosion processes, affecting how the metal interacts with its environment. When the pH is slightly alkaline, it often promotes the formation of stable, protective patinas that shield the steel from further damage. Conversely, highly acidic or highly alkaline conditions accelerate rust formation, as they facilitate the breakdown of protective oxide layers. Understanding how pH levels impact these reactions helps you predict corrosion behavior. By controlling the environment’s pH, you can influence whether your carbon steel forms a durable patina or degrades into rust, allowing for better preservation and maintenance strategies.

Signs of Structural Damage or Pitting

Identifying signs of structural damage or pitting early can save your metal from significant failure. Effective corrosion spotting involves inspecting for deep holes or irregular surfaces that indicate pitting. During a structural assessment, look for these key signs:

Early detection of pitting prevents costly structural failures and ensures safety.

- Visible holes or cavities on the surface

- Flaking or peeling metal layers

- Uneven or rough patches that feel different to the touch

- Areas where the metal appears weakened or thinned

These indicators suggest active corrosion and potential structural compromise. Addressing pitting early prevents further deterioration and costly repairs. Regular inspections are essential for maintaining safety and functionality. If you notice any of these signs, prioritize corrosion spotting and consider professional evaluation to determine the extent of damage and necessary action.

Long-term Effects and Maintenance Indicators

Understanding the long-term effects of corrosion is essential for maintaining the integrity of your metal structures. As corrosion progresses, it can weaken the metal, leading to structural failure if left unchecked. Recognizing signs of advanced corrosion helps you determine when maintenance strategies are needed to prevent further damage. Look for increased rust, pitting, or flaking, which indicate ongoing corrosion progression. Regular inspections are critical to identify these indicators early. Implementing appropriate maintenance strategies, such as cleaning, applying protective coatings, or removing rust, can slow corrosion’s effects. Addressing issues promptly ensures the longevity of your carbon steel and prevents costly repairs. Staying proactive with your maintenance routine helps you maintain safe, durable structures over time.

Frequently Asked Questions

Can Patina and Rust Occur Simultaneously on the Same Surface?

Yes, patina and rust can occur simultaneously on the same surface. You might notice surface discoloration caused by chemical reactions, creating a patina, while rust forms in spots where the metal is exposed to moisture and oxygen. These processes can overlap, especially in humid environments, making it tricky to distinguish between them. Regular maintenance and proper sealing help prevent rust, preserving the desirable patina on your carbon steel.

How Does Environmental Exposure Influence Patina Versus Rust Formation?

Did you know that environmental exposure can accelerate metal deterioration by up to 60%? It markedly influences whether patina or rust forms on carbon steel. Humidity, air quality, and temperature play vital roles. Moist environments promote rust, while controlled conditions encourage a stable patina. You can protect your steel by understanding these environmental factors, preventing unwanted corrosion, and maintaining its appearance and integrity over time.

Are There Specific Cleaning Agents to Prevent Rust but Preserve Patina?

You can prevent rust while preserving patina by using specific cleaning solutions designed for carbon steel, like mild acids or specialized metal cleaners. After cleaning, apply protective coatings such as wax or oil to shield the surface from moisture. These solutions help remove dirt and corrosion without stripping the natural patina, ensuring your metal stays protected and visually appealing over time.

Does the Age of the Metal Affect Its Likelihood to Develop Rust or Patina?

As the metal ages, it becomes more susceptible to corrosion, increasing the chances of rust formation. Older carbon steel tends to develop a patina faster, but its corrosion susceptibility also rises over time. You should regularly monitor and maintain your metal, applying protective coatings or cleaning agents designed to prevent rust while preserving patina. Proper care minimizes the effects of metal aging, helping your piece stay durable and visually appealing longer.

Can Protective Coatings Distinguish Between Preventing Rust and Maintaining Patina?

Protective coatings can effectively prevent rust and help maintain patina, but not all coatings are equal. You should choose coatings designed for surface preservation that allow the patina to develop naturally while blocking moisture that causes rust. Clear sealants or waxes often work well, providing a barrier without altering the metal’s appearance. Proper application guarantees your carbon steel retains its aesthetic and structural integrity, balancing protection with the preservation of its character.

Conclusion

Understanding the dance between patina and rust helps you read your carbon steel’s story. Patina wears a gentle, artistic cloak, while rust whispers of neglect with its rough, corrosive touch. By noticing color, texture, and reaction, you become the detective of your metal’s fate. With this knowledge, you’ll nurture a shimmering, resilient surface—turning your steel into a canvas of history and protection, a silent symphony of care and resilience.