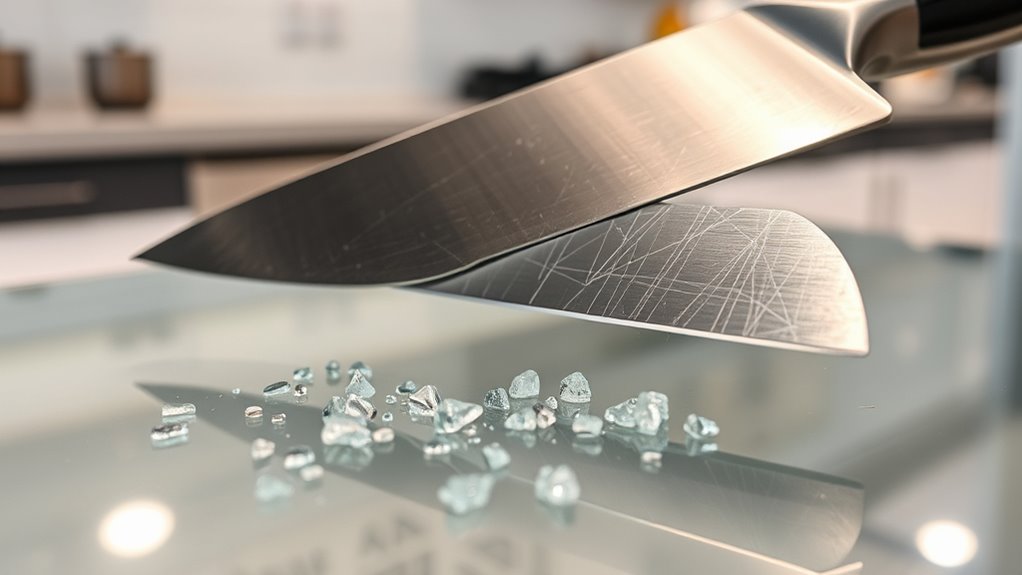

Glass cutting boards are very hard and abrasive, which quickly dulls your knife’s sharp edge. Every cut transfers impact and friction directly onto the blade, causing tiny chips and microabrasions that weaken and blunt it over time. This material’s brittleness also increases the risk of chipping or cracking your knife. If you want to extend your blade’s life and keep it sharp longer, understanding how glass damages knives is essential—more useful tips follow.

Key Takeaways

- Glass’s high hardness causes intense abrasion, microchips, and microfractures that dull knife edges quickly.

- Repeated cutting on glass increases friction and heat, accelerating blade wear and weakening the metal.

- The brittle nature of glass leads to micro-chipping and microcracks, damaging the knife edge over time.

- Glass’s rigid surface transfers impact force directly to the blade, hastening dulling and potential edge deformation.

- Softer materials like wood or plastic reduce friction and impact, helping preserve knife sharpness longer.

The Hardness of Glass and Its Impact on Blades

The hardness of glass considerably affects how it interacts with knives during cutting. Glass hardness determines how resistant it is to scratches and cuts, which directly impacts blade impact. When you cut on glass, its high hardness can cause your blade to meet significant resistance, leading to more force being transferred to the edge. This increased impact accelerates blade dulling, making your knife less sharp over time. Softer materials might absorb some of the force, but glass’s hardness means it pushes back, stressing the blade. As a result, your knife endures greater wear with each cut. Understanding Material hardness helps you realize why cutting on glass can quickly compromise your blade’s edge, emphasizing the importance of choosing appropriate cutting surfaces. The Hardness of glass is a key factor that influences how quickly your knife will dull when used on different surfaces. Additionally, the abrasion resistance of glass exacerbates this effect by resisting deformation and effectively acting as a hard, unyielding surface. The impact force generated during cutting on such a hard surface further accelerates blade dulling and potential damage. Recognizing the wear and tear on your blade can help you make more informed decisions about your cutting habits and tools.

How Cutting on Glass Accelerates Blade Dulling

Cutting on glass causes your knife to face hard surface damage, which wears down the blade faster. The increased friction between the blade and the glass accelerates dulling, making it harder to cut smoothly. Over time, this process shortens your knife’s lifespan and affects its performance. Proper cutting surfaces can help preserve your knife’s sharpness and extend its usability. Using inappropriate surfaces can also pose safety risks by increasing the chance of slips or accidents during cutting. Additionally, choosing appropriate materials like wood or plastic can help protect both your knife and your safety during food preparation. Incorporating modern farmhouse decor trends such as rustic wooden cutting boards can combine style and functionality while protecting your knives.

Hard Surface Damage

Because glass is a hard, brittle surface, cutting on it causes rapid wear and tear on your knives. The surface hardness of glass exceeds that of most knife edges, leading to intense abrasion when you slice. Each cut chips away tiny particles from the knife’s edge, gradually dulling it. Unlike softer surfaces that absorb some force, glass reflects it back, increasing the strain on your blade. Over time, this damage accumulates, creating microchips and dullness that reduce your knife’s sharpness and effectiveness. The relentless hardness of glass doesn’t just wear down the edge—it also causes microfractures along the blade, weakening it structurally. This hard surface damage accelerates dulling, making your knives less precise and more prone to slipping, which can be dangerous during food prep. Additionally, cutting on glass can generate microabrasions that compromise the blade’s structural integrity over time, especially since blade maintenance becomes more difficult with increased microstructural damage.

Increased Blade Friction

When you slice on glass, increased friction between the blade and the surface speeds up the dulling process. This friction generates more blade heat, which weakens the metal’s edge over time. The harder surface of glass requires you to apply greater cutting pressure, forcing the blade to work harder with each cut. As a result, the blade’s edge endures more stress and wears down faster. The constant resistance from the glass surface prevents smooth slicing, causing microscopic chips and dents that compromise sharpness. Over repeated use, this accelerated dulling reduces your knife’s effectiveness and lifespan. To protect your blades, avoid cutting on glass and opt for softer surfaces that reduce friction and cutting pressure, helping your knives stay sharper longer. Additionally, using cutting mats designed for kitchen use can significantly extend the life of your knives by providing a more forgiving surface. Recognizing proper knife care and maintenance practices can further prolong your blade’s sharpness and overall durability. Regularly sharpening and honing your knives can also help maintain their edge and reduce the impact of cutting on hard surfaces. Understanding blade material properties can help you select knives that are more resistant to dulling and damage. Moreover, choosing high-quality knives made from durable materials can make a notable difference in how quickly they dull.

The Science Behind Knife Edge Wear and Tear

Understanding how knife edges wear and tear involves examining the forces and materials at play during cutting. When you slice on a glass surface, the hardness of the glass creates increased blade friction, accelerating wear. The wear process is influenced by the blade coating—some knives have coatings designed to reduce friction, but these can wear down quickly under harsh surfaces. Additionally, edge geometry plays a critical role; a finely honed, narrow edge concentrates force, making it more susceptible to dulling or chipping. As you cut repeatedly, microscopic dents form along the edge, weakening its structure. Over time, this results in a duller, less effective blade. Recognizing how these factors interact helps you understand why glass cutting boards damage your knife edges faster. Proper maintenance techniques can help mitigate some of this wear and prolong your knife’s sharpness. Being aware of material hardness and choosing appropriate cutting surfaces can significantly extend the life of your blades, especially when considering the impact of blade coatings designed to reduce friction and wear. Additionally, understanding blade edge geometry can inform better cutting practices that minimize damage. Using cutting technique with proper angle and pressure can further reduce edge deterioration and extend your knife’s lifespan.

Types of Damage to Your Knife When Using Glass Surfaces

Using a glass cutting board can cause several types of damage to your knife, compromising its sharpness and structural integrity. Because glass isn’t compatible with traditional steel blades, it can lead to micro-chipping and dulling of the edge. The material’s hardness exceeds that of most knife steels, increasing abrasive wear and accelerating edge dulling. This damage stems from poor material compatibility, which causes your blade to scrape against the surface unevenly. Additionally, the surface durability of glass means it’s very hard but also brittle, making it prone to shattering or chipping if used with excessive force. Over time, these factors contribute to a less effective cutting edge, requiring more frequent sharpening and reducing the lifespan of your knife. Understanding material compatibility is key to maintaining your knife’s longevity and performance. Moreover, proper cutting surface selection can significantly extend the life of your blades, especially when considering the abrasiveness of different materials. Recognizing the impact of surface hardness on knife health helps you choose safer and more durable options.

Comparing Glass to Other Cutting Board Materials

When comparing glass to other cutting board materials, you’ll notice differences in hardness and durability. Glass is very hard but can chip or crack more easily than softer options like wood or plastic. Consider knife-friendly alternatives that balance durability with gentleness on your blades. Proper material selection can help extend the lifespan of your knives and make food prep safer and more efficient.

Hardness and Durability

Glass cutting boards are especially harder than many traditional materials like wood or plastic, making them resistant to scratches and cuts from knives. This hardness stems from ceramic properties that give glass its durability and scratch resistance. Unlike softer materials, glass doesn’t easily dent or gouge, maintaining a smooth surface over time. However, this rigidity can be a double-edged sword, as it’s less forgiving to metal compatibility—knives will dull faster when cut on glass. While durable, glass can chip or crack if struck with force, reducing its longevity. Its high hardness makes it ideal for resisting everyday wear, but it also transfers more impact to your knives, contributing to edge dulling. Overall, glass excels in durability but demands careful handling to protect both the board and your blades.

Knife-Friendly Alternatives

Compared to glass, materials like wood and plastic generally offer a more knife-friendly cutting surface. Their material properties allow knives to slide smoothly, reducing edge dulling. Wood, in particular, provides natural elasticity, absorbing some of the impact from cutting, which enhances cutting surface compatibility. Plastic boards are lightweight and easy to sanitize, making them practical for everyday use. Both materials tend to be softer than glass, meaning they don’t dull your knife as quickly. While they may scar or stain over time, they preserve your knife’s edge longer. Overall, choosing wood or plastic helps maintain your knife’s sharpness and ensures a more efficient, comfortable cutting experience. These alternatives are better suited for frequent use without sacrificing your knife’s longevity.

Signs Your Knife Is Dulling Too Quickly

If your knife starts to feel dull more quickly than it used to, it’s a clear sign that it’s losing its edge. You may notice increased effort when cutting and uneven slices. This indicates knife edge fatigue, which happens faster with frequent use on glass cutting boards. Additionally, dullness can stem from improper blade sharpening techniques, which fail to restore the edge properly. Here are some signs to watch for:

- The knife requires more pressure to cut through food

- You experience slipping or inconsistent cuts

- The blade develops nicks or chips easily

If these signs appear, it’s time to revisit your sharpening routine or consider professional sharpening. Dulling happens faster when the edge is weakened, so maintaining proper blade care is essential.

Alternatives to Glass Cutting Boards for Sharpness Preservation

Choosing the right cutting surface can considerably extend the sharpness of your knives. Instead of glass, opt for materials like wood or plastic, which are gentler on your knife edge. Hardwood cutting boards, such as maple or walnut, absorb less shock and wear down your blades slower. Plastic cutting surfaces are lightweight, easy to sanitize, and also preserve your knife’s sharpness effectively. Bamboo is another good alternative, offering durability without dulling edges quickly. Avoid glass or stone surfaces, as they are too hard and cause rapid dulling. By selecting a softer, more forgiving cutting surface, you reduce unnecessary strain on your knife edge, helping it stay sharper longer and ensuring cleaner cuts every time.

Tips for Maintaining Your Knives and Choosing the Right Surface

Maintaining your knives in top condition starts with proper technique and regular care, but selecting the right cutting surface plays a crucial role as well. Choosing the correct surface can extend your blade’s edge and improve knife maintenance. To get the most from your knives, consider these tips:

- Opt for softer surfaces like wood or plastic, which are gentler on blades and help preserve sharpness.

- Avoid glass or stone, as they are too hard and cause rapid dulling.

- Regularly clean and dry your cutting surface to prevent bacteria and maintain a smooth cutting area.

Frequently Asked Questions

Can Using a Glass Cutting Board Damage My Knife’s Handle?

Using a glass cutting board won’t damage your knife’s handle directly. However, it can affect your knife handle durability over time if you’re not careful, especially if the handle is made of wood or less resistant materials. The glass surface itself is resistant to corrosion, but sharp edges or chips can cause accidental slips, potentially damaging the handle or leading to injuries. Always choose a sturdy, well-maintained knife for safety and longevity.

Are There Specific Knives More Resistant to Glass Surface Damage?

Yes, ceramic knives and serrated blades are more resistant to damage from glass surfaces. Ceramic knives have a harder, more durable edge that’s less prone to chipping or dulling, while serrated blades can handle the abrasive glass surface better than straight-edged knives. However, you should still exercise caution, as even these knives can suffer damage if used improperly or with excessive force on glass cutting boards.

How Does Glass Compare to Plastic or Wood in Preserving Knife Edges?

Glass cutting boards are much harder and more abrasive than plastic or wood, which means they damage your knife edges faster. The material hardness and surface abrasiveness of glass cause constant wear on your blades, dulling them quickly. In contrast, plastic and wood are softer and gentler, helping preserve your knife edges longer. So, if you want to keep your knives sharp, avoid glass and opt for softer materials.

Is There a Way to Sharpen Knives That Have Been Dulled by Glass?

You can sharpen knives dulled by glass using proper sharpening techniques. Start with a honing steel to realign the blade, then use a whetstone or electric sharpener suited for your knife’s material. Regular knife maintenance, like honing and avoiding cutting on glass, prolongs sharpness. If your knife is heavily damaged, consider professional sharpening to restore its edge effectively. This guarantees your knives stay sharp and functional for longer.

Does the Thickness of a Glass Cutting Board Affect Its Impact on Knives?

Yes, glass thickness affects its impact on knives. Thicker glass cutting boards tend to absorb more impact, reducing the stress on your knife edges. However, even with increased thickness, glass can still dull your blades over time because of its hardness. Thinner glass boards cause more impact absorption, which can lead to quicker dulling. For preserving knife sharpness, opt for thicker glass boards, but remember they still may not be as gentle as wood or plastic.

Conclusion

Choosing the right cutting surface isn’t just about safety, it’s about preserving your knives’ sharpness over time. When you opt for materials that match your blades’ natural hardness, you often find yourself cutting more efficiently and with less wear. Coincidentally, this means fewer dull blades and less frequent sharpening, saving you time and money. So next time you’re in the market, consider what your knives truly need—sometimes, the best choice is the one you least expect.