Thin blades cut better because they create less resistance, allowing you to slice smoothly and with less effort. Their narrower edge concentrates force, giving you a razor-sharp feel that feels “scary sharp” to the touch. The microgeometry, like bevels and microstructure, also plays a part in how clean and precise your cut is. Keep going, and you’ll uncover how blade design and material choices make all the difference in performance and sharpness.

Key Takeaways

- Thinner blades have less material resistance, allowing them to slice more easily and smoothly through surfaces.

- Reduced thickness concentrates force along a narrow edge, increasing pressure for cleaner, more precise cuts.

- Thin blades produce sharper, finer edges that enhance tactile perception, making them feel “scary sharp” to the touch.

- The microgeometry of thin blades, such as steep bevels, optimizes sharpness and cutting efficiency.

- Proper maintenance and sharpening techniques help thin blades retain their microstructure, sustaining their “scary sharp” feel over time.

The Physics Behind Cutting Efficiency

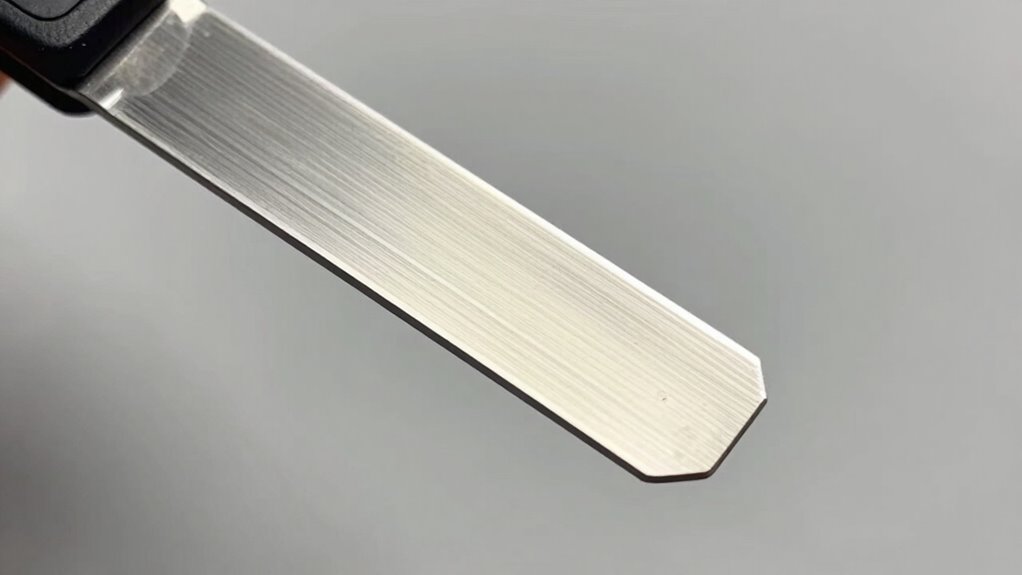

Understanding the physics behind cutting efficiency reveals why thin blades perform better. When you choose a blade, the material matters—stainless steel, carbon steel, or ceramic each affects how smoothly it cuts. A sharper, thinner edge reduces resistance, allowing you to slice through material with less force. The blade’s design, combined with a comfortable ergonomic grip, improves control and precision, minimizing hand fatigue. The grip guarantees you apply consistent pressure and maintain proper angle, which is vital for efficient cutting. Thinner blades concentrate force along a smaller edge, increasing pressure and making cuts cleaner and easier. Additionally, selecting the right blade material can influence durability and overall performance material properties. By selecting the right blade material and guaranteeing a secure, ergonomic grip, you optimize the physics that make thin blades cut more effectively and feel incredibly sharp. Moreover, understanding cutting mechanics helps in choosing the optimal blade for different tasks, ensuring efficiency and safety.

How Blade Thickness Affects Cutting Performance

Thinner blades reduce material resistance, making cutting easier and more efficient. They also give you greater control for precise, accurate cuts. Plus, their reduced thickness allows for faster cutting speeds without sacrificing performance. Additionally, understanding blade sharpness can further enhance your cutting experience by ensuring clean, smooth cuts every time. Being aware of blade material quality can also influence durability and cutting performance over time. Recognizing the importance of blade manufacturing precision can help you select tools that maintain optimal sharpness and longevity. Incorporating proper blade maintenance techniques ensures your blades stay in top condition for longer periods.

Reduced Material Resistance

When a blade is thinner, it encounters less resistance from the material you’re cutting, allowing it to slice through more easily. This reduction in resistance means less force is needed, making cutting smoother and more efficient. Thinner blades also offer greater blade flexibility, helping them conform to uneven surfaces and reducing the chance of binding or bending. Additionally, manufacturing tolerances are tighter with thinner blades, ensuring precise edges and consistent performance. This precision minimizes material deformation and enhances control. As a result, you’ll experience cleaner cuts with less effort. The combination of reduced resistance, increased flexibility, and tighter manufacturing tolerances makes thin blades superior for cutting tasks demanding accuracy and ease. Proper blade selection also benefits from understanding blade geometry, which influences cutting performance and safety. A thorough understanding of material properties can further optimize blade choice and cutting efficiency. Recognizing how blade thickness directly impacts cutting behavior can help in selecting the right tool for specific applications. Incorporating advanced manufacturing techniques can also improve the quality and performance of thin blades, especially when combined with material science to develop more durable and precise blades.

Enhanced Precision Control

Because a blade’s thickness directly influences how precisely it can follow a cut line, thinner blades give you better control over your work. They bend more easily, enhancing blade flexibility, which allows for cleaner, more accurate cuts. Thinner blades also reduce material vibration, minimizing wobbling that can throw off your line. To see how these factors matter, consider this table:

| Factor | Impact |

|---|---|

| Blade Flexibility | Better bending for precise, smooth cuts |

| Material Vibration | Less wobbling, cleaner cut lines |

| Control | Increased ability to follow intricate curves |

With thinner blades, you gain refined control, making your cuts more accurate and consistent, especially on delicate or detailed work.

Increased Cutting Speed

Reducing blade thickness allows for faster cutting speeds by decreasing resistance and friction during the cut. Thinner blades encounter less material to push through, enabling smoother, quicker cuts. This efficiency stems from improved cutting dynamics, but it also depends on manufacturing processes that guarantee blade durability despite the reduced thickness. Proper blade design and material selection are essential to ensure these blades perform reliably over time. Incorporating advanced sound healing science techniques into manufacturing can further optimize blade vibrations for enhanced performance.

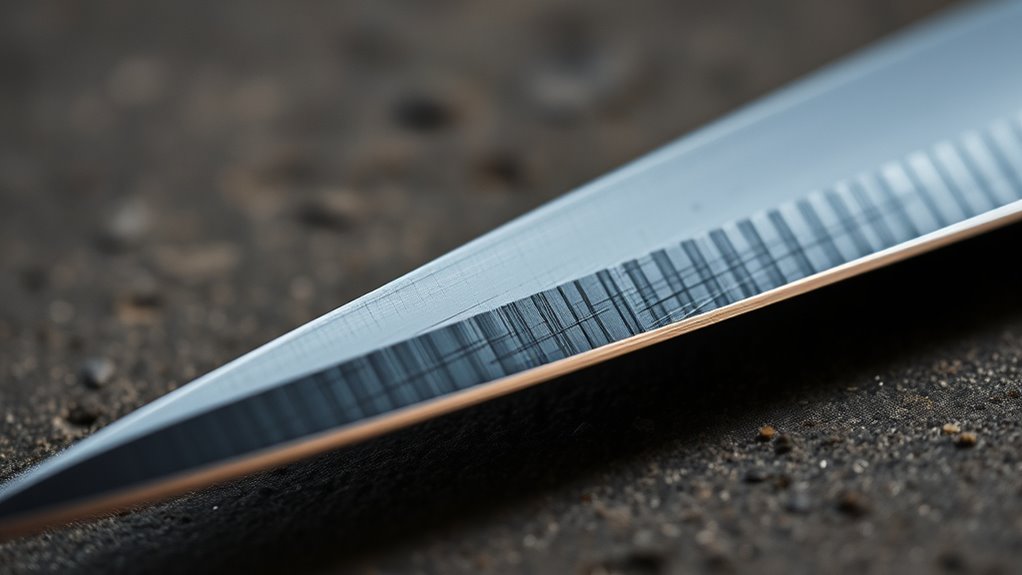

The Role of Edge Geometry and Bevels

Your blade’s edge geometry and bevels play a vital role in cutting performance. Precise bevel angles and microgeometry details determine how cleanly and easily your blade slices through material. Understanding the differences between hollow and convex bevels helps you choose the right edge for sharper, more efficient cuts. Proper edge maintenance also ensures your blades stay at optimal sharpness for longer periods. Additionally, knowing how edge geometry influences cutting efficiency can help you select the most suitable blade for different tasks and materials. Recognizing cutting mechanics can further enhance your understanding of how blade design impacts overall performance.

Bevel Angle Precision

The accuracy of your bevel angle directly influences how effectively a blade cuts and how sharp it feels. Small deviations can cause uneven cuts or dull edges faster. To guarantee ideal performance, focus on:

- Maintaining consistent bevel angles during sharpening for a uniform edge.

- Selecting blade materials that respond well to precise angles, enhancing durability.

- Considering handle ergonomics, which affect your control when fine-tuning the bevel.

- Paying attention to yarn weight and stitch type when working on projects like scarves, since these factors can impact how well a blade slices through different materials.

A precise bevel angle creates a sharper edge that cuts smoothly and lasts longer. It also ensures the blade works harmoniously with your grip, reducing fatigue. Remember, even small inaccuracies in angle can translate into significant differences in cutting performance. Proper attention to bevel angle precision makes your blade feel ‘scary sharp’ and improves overall handling.

Edge Microgeometry Details

Because edge microgeometry plays a crucial role in cutting performance, understanding how bevel angles and edge profiles interact can make a significant difference in your results. Your blade microgeometry, including the edge microstructure, determines how cleanly and efficiently a blade cuts. A finer, more consistent edge microstructure creates a sharper, more durable edge by reducing micro-chipping and tearing. Bevel angles influence this microgeometry; a steeper bevel can produce a thinner, more precise edge, while a shallower bevel offers greater strength. The shape and profile of the edge—whether flat, convex, or micro-beveled—also affect how the microstructure interacts with material. Paying attention to these details ensures your blades perform at their best, delivering smooth, effortless cuts and maintaining their ‘scary sharp’ feel. Additionally, considering the edge microstructure can help you customize blades for specific tasks, enhancing both efficiency and safety.

Hollow Versus Convex

Hollow and convex edge geometries each shape how a blade interacts with material, influencing cutting performance and durability. Hollow edges are created through grinding, resulting in a thinner, sharper bevel that cuts more easily but may be less durable. Convex edges are formed via grinding or polishing, producing a rounded bevel that enhances blade durability and strength.

Consider these key points:

- Hollow edges excel at slicing smoothly but can dull faster due to their thin profile.

- Convex edges offer increased blade durability, ideal for heavy-duty tasks.

- Manufacturing processes determine the precision of these geometries, affecting edge retention and performance.

Choosing between hollow and convex depends on your needs; understanding their role in edge geometry helps you optimize cutting efficiency and longevity.

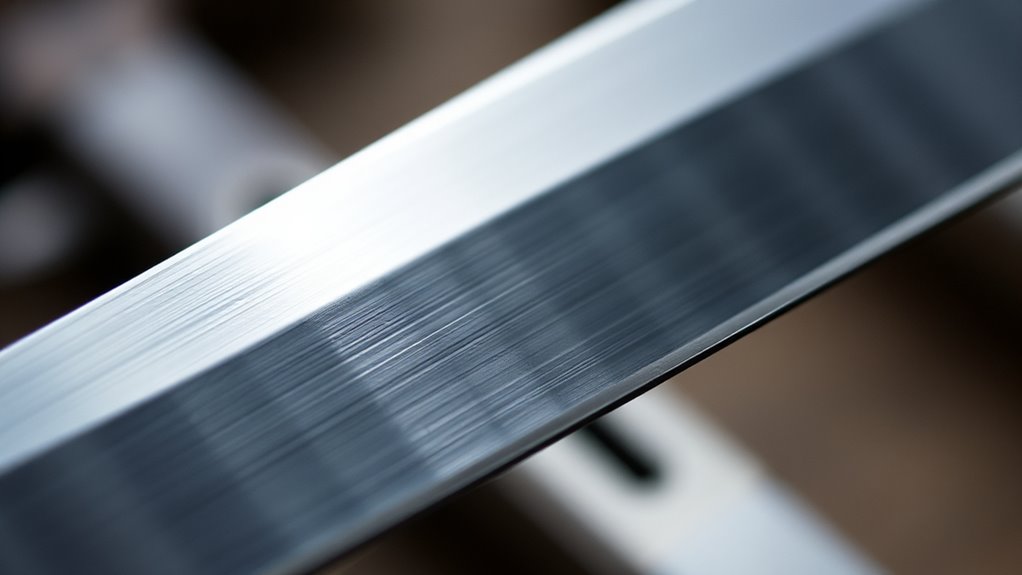

Sharpening Techniques for Thin Blades

Sharpening thin blades requires a delicate touch and precise technique to maintain their edge and avoid damage. You need to contemplate blade flexibility—applying even pressure ensures you don’t bend or chip the edge. Proper handle ergonomics help you control the angle and pressure, preventing slips. Imagine the sharpening process as a balanced dance:

| Blade Flexibility | Handle Ergonomics | Sharpening Pressure |

|---|---|---|

| Slight bend aids edge contact | Fits comfortably in your hand | Gentle, consistent strokes |

| Too stiff, risks uneven edge | Reduces fatigue | Avoid pressing too hard |

| Flexibility allows precise angle | Promotes steady control | Maintain steady hand movements |

| Proper grip ensures safety | Keeps blade stable | Focus on light, deliberate passes |

| Flexibility preserves integrity | Enhances precision | Regularly check for sharpness |

Additionally, ensuring your sharpening tools are properly maintained can make a significant difference in achieving a scary sharp edge. Paying attention to blade material properties can also influence the sharpening approach and results. Understanding the role of blade flexibility is crucial for preventing damage and improving sharpening efficiency, especially with delicate or thin blades. Regularly inspecting your blades for signs of wear or damage can help you adjust your sharpening technique accordingly, especially when working with body piercing tools.

Why Thin Blades Feel Incredibly Sharp to the Touch

Have you ever noticed how thin blades feel almost unnervingly sharp to the touch? That’s because their minimal blade thickness concentrates the cutting force into a tiny edge, making it seem razor-sharp. Here’s why:

- Reduced blade thickness means less material to resist your touch, increasing the sensation of sharpness.

- Lower cutting force needed to make contact, which feels less resistant and more precise.

- The edge’s fine point concentrates pressure, creating an almost “scary” sharp feeling when you run your finger over it.

This sensation isn’t just perception; it’s rooted in the physics of blade thickness and cutting force. The thinner the blade, the more delicate and sharp it feels, even if the actual cutting ability is what truly counts.

Material Choices and Their Impact on Blade Sharpness

The choice of material profoundly influences how sharp a blade can become and how long that edge lasts. Different blade materials, such as high-carbon steel, stainless steel, or exotic alloys, each have unique properties affecting sharpness retention. For example, steels with higher hardness can hold a sharper edge longer, but may be more brittle. Conversely, softer steels are easier to sharpen but dull faster. Selecting the right blade material and optimizing the manufacturing process ensures you get a sharper, longer-lasting edge. Material properties significantly impact the blade’s cutting performance and how “scary sharp” it can feel. Additionally, the manufacturing process determines the blade’s final sharpness and durability, emphasizing the importance of precision techniques like grinding and honing.

Comparing Thin and Thick Blades in Various Applications

When choosing between thin and thick blades, understanding their specific strengths and limitations is essential for different applications. Thin blades excel in precision cuts, thanks to their sharpness and minimal resistance, making them ideal for intricate work. Thick blades, however, offer greater blade durability and stability, suitable for heavy-duty tasks. Here are key factors to consider:

- Blade durability: Thick blades generally last longer under tough conditions.

- Manufacturing tolerances: Thin blades require tighter tolerances to maintain sharpness and prevent bending.

- Application-specific performance: Thin blades cut smoother and more precisely, while thick blades handle more force without deforming.

Knowing these differences helps you select the right blade for your project, ensuring ideal performance and longevity.

Common Misconceptions About Blade Sharpness and Safety

Many people assume that a blade’s sharpness directly correlates with its safety, but this isn’t always the case. Sharp blades made from quality blade materials actually require less force to cut, reducing slippage and accidents. The misconception is that a dull blade is safer because it’s less likely to cause deep cuts, but a dull blade can be more dangerous because it requires more effort, increasing your chance of slips. Proper safety equipment, like cut-resistant gloves and eye protection, is essential regardless of blade sharpness. Remember, a well-sharpened blade is safer because it cuts efficiently with less force. Don’t rely on dull blades or assumptions—use good blade materials and proper safety gear to stay safe during your work.

Tips for Maintaining and Extending the Life of Thin Blades

To keep your thin blades performing at their best, regular maintenance is essential. Proper care not only extends blade longevity but also maintains their sharpness and cutting efficiency. Here are three maintenance tips to optimize your blades:

- Clean blades after each use to remove debris and prevent corrosion.

- Store blades in a dry, protected place to avoid moisture damage.

- Sharpen blades regularly with a proper sharpening stone or tool to maintain a scary sharp edge.

Following these simple steps ensures your blades stay sharp longer and perform consistently. Proper maintenance reduces the need for frequent replacements, saving you money and effort. Remember, a well-maintained blade cuts cleaner, smoother, and safer, ultimately giving you better results and extending its lifespan.

Frequently Asked Questions

How Does Blade Thickness Influence Cutting Noise?

Blade thickness substantially influences cutting noise by affecting blade resonance and noise frequency. Thinner blades tend to vibrate more easily, creating higher resonance and noise frequency, which results in louder, sharper sounds. Conversely, thicker blades dampen vibrations, reducing resonance and noise levels. So, when you use a thin blade, expect a louder, more intense cut, while thicker blades produce quieter, more controlled cuts due to less resonance.

Can Thin Blades Be More Prone to Breaking?

Thin blades can be more prone to breaking because of their blade brittleness, making them less resistant to impact. You might notice they chip or snap easier if you apply too much force or use them on hard materials. However, their edge durability remains excellent when handled carefully. While they’re incredibly sharp and precise, you should treat them delicately to avoid damaging the blade or risking breakage.

Why Do Thin Blades Require Different Storage Methods?

You should store thin blades differently because they’re more prone to blade corrosion and damage. Keep them in a dry, protected environment to prevent rust and maintain their sharpness. Use blade guards or sheaths for storage to guarantee safety and avoid accidental cuts. Proper storage not only extends the life of your blades but also keeps your workspace safe, reducing the risk of injury from handling dull or corroded blades.

Are Thin Blades Suitable for All Materials?

Coincidentally, thin blades aren’t suitable for all materials because their blade durability varies with material compatibility. You’ll find they excel with softer or delicate materials, offering a cleaner, sharper cut. However, when working with tougher, harder substances, they might bend or chip, reducing their effectiveness. Always consider the specific material you’re cutting and choose a blade designed for that purpose to guarantee safety and peak performance.

How Does Temperature Affect the Sharpness of Thin Blades?

Temperature impacts the sharpness of thin blades by causing heat impact, which can soften the blade’s edge. Excess heat can lead to material deformation at the cutting edge, reducing sharpness and effectiveness. You’ll notice that when blades get too hot, they become dull faster or lose their precise cutting ability. To keep your thin blades sharp, avoid prolonged contact with high heat sources and allow them to cool between uses.

Conclusion

Remember, a thin blade isn’t just sharper—it’s a delicate balance of physics and craftsmanship. As you wield it, feel the power of precision, the thrill of slicing effortlessly through your task. But with that power comes responsibility—respect its edge, maintain it well, and avoid rushing. Embrace the beauty of a finely honed blade, for in its sharpness lies both mastery and mastery’s challenge. Let your skill and care keep it ever at its best.