When you cut with a flat edge, you’ll notice smooth, effortless slicing and food releasing easily. Hollow grinds feel razor-sharp and thin, making delicate tasks like peeling or slicing very smooth, but they require gentle handling. Convex edges offer more support and durability, giving you a solid feel during chopping, especially with tough ingredients. Each shape influences resistance and control—keep exploring to discover how these differences can improve your cutting experience even more.

Key Takeaways

- Flat grind offers smooth, effortless slicing with minimal resistance, providing a stable and predictable cutting feel.

- Hollow grind feels extremely sharp and delicate, enabling precise, effortless cuts with less force required.

- Convex grind provides a sturdy, supported edge that may feel more resistant but offers greater control during heavy chopping.

- Flat and hollow edges slide easily through food, while convex edges may push aside ingredients for stability.

- Your cutting experience varies: flat and hollow feel smooth and slicing, convex emphasizes control and power for tough tasks.

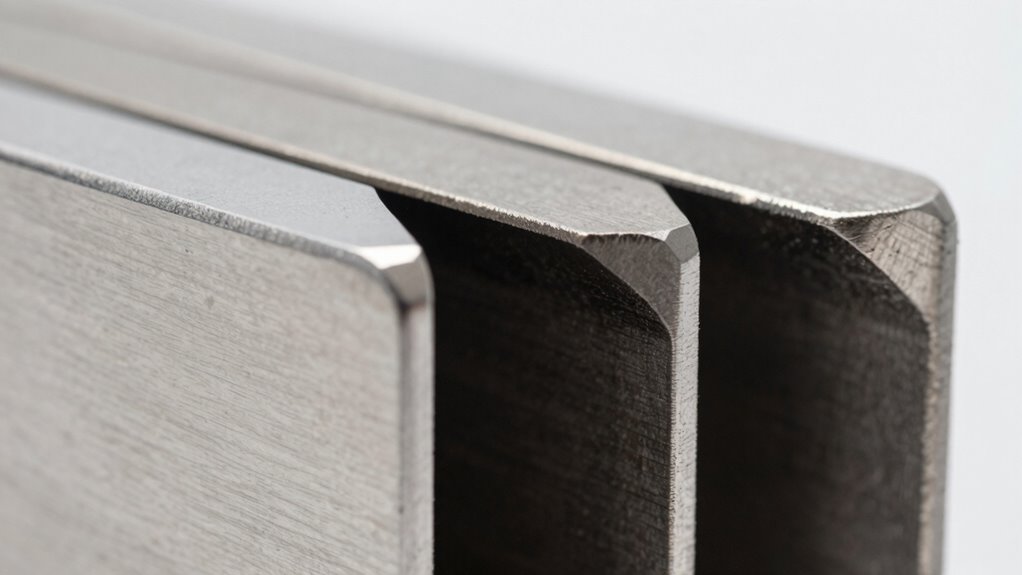

Understanding the Flat Grind and Its Cutting Feel

The flat grind is one of the most versatile and common blade geometries, making it a popular choice for many users. When you cut with a flat grind, you’ll notice a smooth, effortless glide through food, thanks to its straight slope from spine to edge. This design creates less resistance, so slicing feels clean and controlled. The symmetrical bevels form a steep V-shape, offering a balanced combination of sharpness and durability. You’ll find that this grind provides moderate edge strength, making it suitable for a wide range of tasks like slicing vegetables, meats, or general kitchen work. Additionally, the flat grind’s edge consistency ensures predictable performance across different cutting tasks, enhancing both precision and ease of use. This geometric simplicity also makes sharpening straightforward, maintaining the blade’s sharpness over time. Overall, the flat grind delivers a predictable, comfortable cutting experience, especially when you want precision without sacrificing ease of use or maintenance.

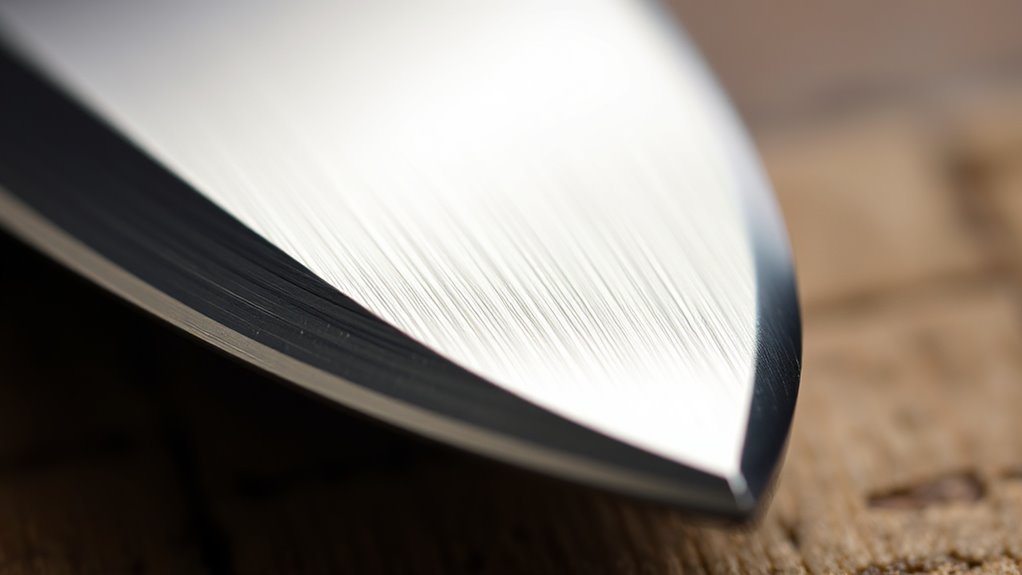

The Precision of Hollow Grind and Its Impact on Slicing Experience

Because the hollow grind features a concave shape formed by grinding against a wheel, it creates an extremely thin and sharp cutting edge that excels at slicing. This precision results in a knife that glides effortlessly through soft foods like fish and meat, providing a clean, smooth cut. The thin edge reduces resistance, making slicing feel almost effortless and more controlled. Additionally, the hollow grind’s edge geometry can help you select the right blade for your specific needs. The blade maintenance required to keep the hollow grind sharp involves careful honing and occasional sharpening to prevent dulling. Regular inspection of the edge is essential, as the hollow grind’s delicate sharpness makes it more susceptible to damage from improper use. However, this sharpness comes with a trade-off: the edge is more delicate and prone to chipping or rolling during heavy-duty tasks. You’ll notice that the hollow grind’s precision enhances fine work like skinning or detailed carving, but it requires careful maintenance to preserve its sharpness and avoid damage. Overall, the hollow grind delivers exceptional slicing performance for light, precise cutting tasks.

The Strength and Durability of Convex Grind During Heavy-Duty Tasks

Convex grind’s outward curve from spine to edge provides exceptional support, making it highly resistant to damage during heavy-duty tasks. Its thick mid-blade steel enhances durability, allowing you to chop, split, or handle tough materials without concern. Here’s what makes it stand out:

- High edge strength resists chipping and rolling under pressure.

- Thick steel reinforcement ensures the edge maintains integrity during tough use.

- Micro-bevels after sharpening boost resilience against shocks.

- Supportive curve distributes force evenly, reducing stress on the edge.

This design is perfect for demanding tasks where durability matters most. While maintenance can be trickier, the convex grind’s robustness makes it ideal for chopping, heavy-duty work, and dealing with shock-prone situations, giving you confidence in high-stress environments.

How Edge Geometry Affects Resistance and Food Release

Your knife’s edge geometry directly impacts how much resistance you encounter and how easily food releases. Flat grinds tend to reduce cutting resistance and promote smooth food release, making them versatile for many tasks. Meanwhile, hollow and convex edges can influence performance differently, especially with delicate or tough ingredients. Understanding UST projectors can help optimize your home theater setup for an immersive viewing experience. Additionally, the choice of edge geometry can be influenced by the geological features of the knife’s material, affecting durability and performance over time. Recognizing how material properties impact the edge’s behavior can further assist in selecting the best geometry for your specific usage. Proper selection of body jewelry materials can also enhance the longevity and comfort of your knife’s edge, especially if you frequently work with sensitive ingredients. Awareness of industry trends in knife design can guide you toward innovations that improve cutting efficiency and maintenance.

Cutting Resistance Variations

Edge geometry directly influences how easily a knife slices through food and how well it releases debris. Your experience varies with different profiles:

- Flat grind offers low resistance, making slices smooth and effortless across various foods.

- Hollow grind provides minimal friction, resulting in razor-sharp cuts ideal for delicate tasks.

- Convex grind increases resistance due to its thicker profile but offers stability during chopping.

- The shape also affects food release; flat and hollow edges tend to slide through easily, while convex edges can sometimes push food aside, requiring more pressure.

- Additionally, understanding edge maintenance is crucial since different geometries may require specific sharpening techniques to maintain their performance.

Understanding these variations helps you anticipate how your knife will perform in different scenarios and adjust your technique accordingly. The right edge profile ensures efficient cutting with less effort and cleaner results.

Food Release Efficiency

The shape of a knife’s edge substantially influences how easily it releases food during cutting. A flat grind’s smooth, even bevel allows for minimal friction, helping food slide off with less resistance. It’s versatile for various tasks but may trap sticky ingredients slightly more than other geometries. Hollow grinds, with their thin, concave profile, excel at slicing delicate items like fish or soft fruits because they create less contact surface area, reducing sticking. However, their narrow edges can sometimes cause food to cling if not sharpened properly. Convex edges, being rounded and thicker, support clean release even with tough or sticky foods. Their robust profile prevents food from catching, making them ideal for chopping or heavy-duty use where food tends to stick. Each geometry’s design directly impacts how smoothly food clears the blade.

Maintenance Techniques and Their Influence on Cutting Performance

Maintaining consistent sharpening angles guarantees your knife’s edge stays effective and reliable. Proper surface preservation techniques, like using the right stones or rods, prevent unnecessary wear and damage. These practices directly impact the knife’s durability and cutting performance over time.

Sharpening Angle Consistency

Achieving consistent sharpening angles is essential for preserving a knife’s cutting performance, as even slight deviations can substantially impact edge durability and efficiency. To maintain this consistency:

- Use a sharpening guide or jig to hold the correct angle throughout each stroke.

- Keep your strokes uniform in pressure and motion to avoid uneven wear.

- Regularly check your angle with a protractor or angle guide for accuracy.

- Practice slow, controlled movements to develop muscle memory for maintaining the correct angle.

Surface Preservation Methods

Proper surface preservation methods are essential for maintaining a knife’s cutting performance and prolonging its lifespan. Regular cleaning, proper storage, and correct sharpening techniques prevent corrosion, dulling, and surface damage. Using a damp cloth after use and drying thoroughly helps reduce moisture buildup. Storing your knife in a knife block, sheath, or on a magnetic strip keeps the blade protected from impacts. For sharpening, choose the right rods or stones based on your grind type, and avoid aggressive abrasive materials that can scratch or deform the surface. The table below highlights key preservation methods and their effects:

| Method | Purpose | Impact on Performance |

|---|---|---|

| Cleaning & Drying | Prevent corrosion & rust | Maintains smooth surface |

| Proper Storage | Avoid impacts & scratches | Preserves edge integrity |

| Regular Sharpening | Restore sharpness & surface finish | Ensures consistent cutting |

| Honing Techniques | Realign edge & smooth surface | Enhances cutting precision |

| Use of Cutting Boards | Protects blade surface | Extends surface quality |

Additionally, choosing the right surface preservation methods can significantly influence the cutting performance by maintaining the integrity of the blade’s surface over time. Incorporating proper maintenance techniques ensures your knife remains effective and safe to use longer-term. Consistent application of these methods supports the surface quality and overall durability of your knife. Proper handling and understanding of surface integrity are crucial for optimal results in your cutting tasks.

Impact on Edge Durability

The way you perform maintenance techniques directly influences your knife’s edge durability and its ability to cut effectively over time. Proper upkeep prevents damage and preserves performance. Here are key factors:

- Regularly sharpening with the correct angle maintains a sharp edge and prevents dullness.

- Using ceramic rods for hollow grinds helps preserve the delicate concave surface without chipping.

- Applying micro-bevels after sharpening strengthens the edge, especially on convex blades.

- Choosing the right cutting surface, like wood, reduces stress on the edge, preventing chips and rolls.

Practical Scenarios: Choosing the Right Grind for Different Tasks

Choosing the right grind depends on the specific tasks you plan to tackle in the kitchen or workshop. If you need a versatile knife for general slicing and prep work, a flat grind is your best option. Its balanced edge makes it suitable for a wide range of materials. For delicate tasks like peeling, skinning, or precision cuts, a hollow grind excels with its razor-sharp, thin profile that reduces resistance. When chopping tough ingredients or heavy-duty work, a convex grind provides durability and strength, resisting chips and deformation. Consider the task’s demands and material type when selecting a grind. For softer foods, hollow grinds shine. For precision and finesse, flat grinds work well. For heavy-duty kitchen chores, go with convex for maximum resilience.

Recognizing Wear and Damage Based on Cutting Feel

As your knife begins to wear or sustain damage, you’ll notice changes in how it feels when cutting. Here are key signs to watch for:

- Rough or snagging cuts – The blade drags or catches on food, indicating dullness or chips.

- Increased force needed – You feel more resistance, suggesting the edge has rolled or become dull.

- Uneven slicing – Cuts no longer glide smoothly, hinting at a damaged or uneven edge.

- Food tearing or crushing – The blade fails to slice cleanly, often due to a chipped or rounded edge.

Recognizing these feels helps you decide whether to sharpen, hone, or replace your knife. Trust your senses; a sharp, smooth cut is a sign of a healthy edge.

Frequently Asked Questions

How Does Edge Geometry Influence Knife Control During Detailed Cuts?

Your knife’s edge geometry directly impacts control during detailed cuts. A flat grind offers steady, predictable slicing, making precise work easier. Hollow grinds provide ultra-sharp, thin edges that excel at delicate tasks, but require finesse to avoid chipping. Convex edges give you robust support, making control for intricate cuts more stable, especially when applying pressure. Choose the grind based on your task to maximize control and precision.

Can Different Grinds Be Combined for Specialized Cutting Tasks?

Think of your knife as a symphony of edges working together. You can combine different grinds, like a flat for versatile slicing and a hollow for precision, to tackle specialized tasks. This hybrid approach gives you the best of both worlds—speed, control, and finesse. Just remember, blending grinds requires careful sharpening and maintenance, but it’s like having a custom tool tailored perfectly to your cutting needs.

What Are Signs of Improper Sharpening for Each Grind Type?

You’ll notice improper sharpening when your knife feels uneven or dull after honing. For flat grinds, edges may appear chipped or uneven, causing inconsistent cuts. Hollow grinds might show a dull or rounded edge, reducing precision. With convex edges, you may feel difficulty in maintaining a sharp, uniform cut, or notice chips from over-sharpening. Always check for smoothness, symmetry, and sharpness to guarantee proper sharpening for each grind type.

How Does Steel Hardness Affect Performance Across Grinds?

You might think softer steel is better for easy sharpening, but harder steel actually boosts performance across all grinds. It keeps a sharper edge longer and resists dulling, especially with convex blades that require precision. While soft steel may seem forgiving, it wears down faster, reducing cutting efficiency. Hard steel provides durability and maintains a keen edge, making it ideal for versatile and heavy-duty tasks across flat, hollow, and convex edges.

Are Certain Grinds Better Suited for Specific Kitchen Environments?

You’ll find that flat grinds are best for versatile kitchen use, perfect for slicing and general tasks. Hollow grinds excel in delicate tasks like filleting or precise cuts, making them ideal for seafood or meats. Convex grinds are great for heavy-duty tasks, like chopping and cutting through tough ingredients. Your choice depends on your cooking style; each grind type suits specific environments, enhancing performance and ease of use.

Conclusion

Think of your knife as a trusty steed—each grind type a different saddle, shaping your ride. Flat edges glide smoothly, hollow grounds slice with finesse, and convex forms brave tough terrain. By understanding these differences, you’ll steer your culinary journey confidently, avoiding pitfalls and enhancing your skill. Mastering edge geometry is like finding the perfect saddle: it transforms your task from a rough ride to a smooth, enjoyable adventure in the kitchen.